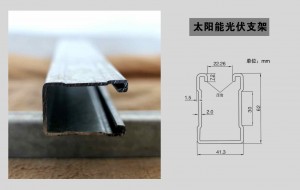

Tam sim no, txoj kev tiv thaiv xeb tseem ceeb ntawm cov hlau photovoltaic bracket siv kub dip galvanized 55-80μm, txhuas alloy siv anodic oxidation 5-10μm.

Aluminium alloy nyob rau hauv ib puag ncig huab cua, nyob rau hauv thaj chaw passivation, nws qhov chaw tsim ib txheej ntawm cov zaj duab xis oxide ntom ntom, cuam tshuam qhov kev sib cuag ntawm cov khoom siv aluminium matrix nrog huab cua ib puag ncig, yog li nws muaj kev tiv thaiv corrosion zoo heev, thiab tus nqi corrosion txo qis nrog lub sijhawm ntev.

Cov hlau nyob rau hauv cov xwm txheej ib txwm muaj (C1-C4 pawg ib puag ncig), 80μm galvanized tuab tuaj yeem ua kom siv tau ntau dua 20 xyoo, tab sis nyob rau hauv cov chaw lag luam uas muaj av noo siab lossis ntug dej hiav txwv salinity siab lossis txawm tias dej hiav txwv kub ntxhov, qhov kev xeb ntawm galvanization yuav tsum ntau dua 100μm, thiab qhov xav tau kev saib xyuas tsis tu ncua txhua xyoo.

Kev sib piv ntawm lwm yam

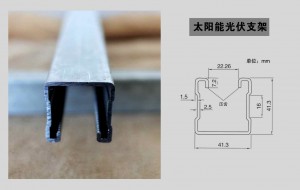

1) Qhov Zoo Li Cas: Cov qauv txhuas ua los ntawm cov hlau muaj ntau hom kev kho saum npoo, xws li anodic oxidation, tshuaj polishing, fluorocarbon spraying, thiab electrophoretic painting. Qhov zoo li cas zoo nkauj heev thiab tuaj yeem hloov kho rau ntau yam kev cuam tshuam corrosive ntawm ib puag ncig.

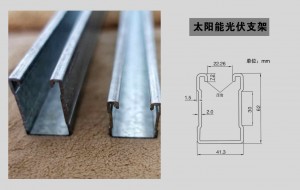

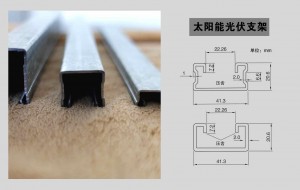

Cov hlau feem ntau yog kub dip galvanized, txau saum npoo, pleev xim thiab lwm yam.

(2) kev sib txawv ntawm qhov sib txawv: cov txhuas alloy profiles feem ntau yog ua tiav hauv extrusion, casting, bending, stamping thiab lwm txoj kev. Kev tsim khoom extrusion tam sim no yog hom kev tsim khoom tseem ceeb, los ntawm kev qhib lub pwm extrusion, tuaj yeem ua tiav cov khoom ntawm txhua qhov kev sib txawv ntawm qhov sib txawv, thiab qhov ceev ntawm kev tsim khoom yog qhov ceev heev.

Feem ntau cov hlau siv rau hauv kev nias rau cov menyuam, kev tsim khoom, kev khoov, kev ntaus thiab lwm yam. Kev nias rau cov menyuam tam sim no yog qhov tseem ceeb ntawm kev tsim cov hlau txias. Kev hloov pauv ntawm qhov seem yuav tsum tau hloov kho los ntawm lub log siab rau cov menyuam, tab sis lub tshuab feem ntau tsuas yog tuaj yeem tsim cov khoom zoo sib xws tom qab kev hloov kho qhov loj me, thiab cov duab ntawm qhov seem tsis tuaj yeem hloov pauv, xws liC beam, Z-beam thiab lwm yam kev hla. Txoj kev tsim khoom siv roller pressing yog qhov ruaj khov dua, qhov ceev ntawm kev tsim khoom sai dua.

Kev sib piv kev ua tau zoo tag nrho

(1) Cov ntaub ntawv txhuas alloy yog lub teeb hauv qhov zoo, zoo nkauj hauv qhov tsos, zoo heev tiv taus corrosion, feem ntau siv rau hauv cov chaw nres tsheb fais fab ru tsev uas xav tau kev thauj khoom, muaj zog corrosive ib puag ncig, xws li cov chaw nres tsheb fais fab cog tshuaj, thiab lwm yam. Aluminium alloy ua lub bracket yuav muaj cov txiaj ntsig zoo dua.

(2) Lub zog siab ntawm cov hlau, me me deflection thiab deformation thaum dais cov khoom thauj, feem ntau siv rau hauv cov xwm txheej ib txwm muaj ntawm lub chaw nres tsheb fais fab lossis siv rau cov khoom ntawm lub zog yog qhov loj heev. Tsis tas li ntawd,galvanized c channelsiv tau los tsim cov thoob, cov loaders, cov tsheb thauj khoom pov tseg, cov crushers, cov hmoov xaiv,Galvanized Channeltiv taus txhua yam kev hnav thiab tsim kua muag los ntawm ntau yam pob zeb, xuab zeb thiab xuab zeb. Nrog kev ua tau zoo heev ntawm kev vuam, lub zog cuam tshuam thiab kev ua haujlwm khoov, tsim nyog rau kev ua haujlwm hauv qhov chaw muaj zog abrasive, xws li cov pob zeb muaj zog thiab cov ntaub ntawv corrosive.

(3) Tus nqi: Feem ntau, lub zog cua yooj yim yog 0.6kN / m2, qhov dav yog qis dua 2m, thiab tus nqi ntawm txhuas alloy stent yog 1.3-1.5 npaug ntawm cov qauv hlau stent. (Xws li xim hlau ru tsev) txhuas alloy bracket thiab hlau qauv bracket tus nqi sib txawv yog qhov me me, thiab hais txog qhov hnyav txhuas alloy yog sib dua li hlau bracket, yog li nws zoo heev rau chaw nres tsheb fais fab ru tsev.

Lub sijhawm tshaj tawm: Lub Ob Hlis-19-2025