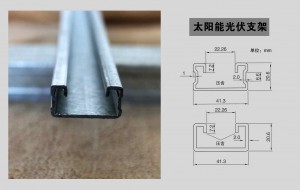

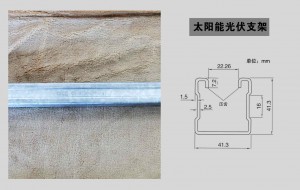

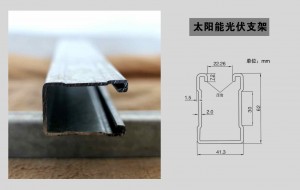

Okwangoku, indlela ephambili yokulwa nokugqwala yentsimbi ye-photovoltaic bracket isebenzisa i-hot dip galvanized 55-80μm, i-aluminiyamu ingxubevange isebenzisa i-anodic oxidation 5-10μm.

I-aluminium alloy kwindawo yomoya, kwindawo yokudlula, umphezulu wayo wenza umaleko wefilimu ye-oxide exineneyo, ethintela ukudibana komphezulu we-aluminium matrix esebenzayo nomoya ojikelezileyo, ngoko ke inokumelana okuhle kakhulu nokugqwala, kwaye izinga lokugqwala liyancipha njengoko ixesha liqhubeka.

Intsimbi kwiimeko eziqhelekileyo (indawo yodidi lwe-C1-C4), ubukhulu be-galvanized obuyi-80μm bunokuqinisekisa ukusetyenziswa kweminyaka engaphezu kwama-20, kodwa kwiindawo zoshishino ezinomswakama ophezulu okanye ulwandle olunetyuwa eninzi okanye namanzi olwandle ashushu, izinga lokugqwala liyakhawuleza, ubungakanani be-galvanization kufuneka bube ngaphezu kwe-100μm, kwaye kufuneka kugcinwe rhoqo minyaka le.

Ukuthelekiswa kwezinye izinto

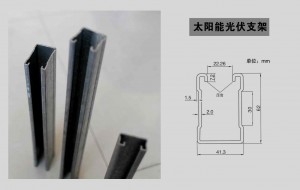

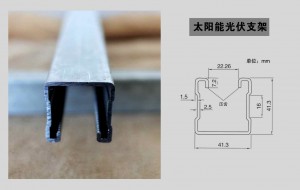

1) Inkangeleko: Iiprofayili ze-aluminium alloy zineentlobo ezininzi zonyango lomphezulu, ezifana ne-anodic oxidation, i-chemical polishing, i-fluorocarbon spray, i-electrophoretic painting. Inkangeleko intle kwaye inokuziqhelanisa nemiphumo eyahlukeneyo yokubola okunamandla kwendalo.

Intsimbi ngokubanzi igqunywe nge-hot dip galvanized, itshizwa ngaphezulu, ipeyinti egqunywe njalo njalo.

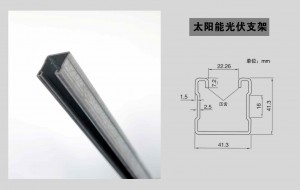

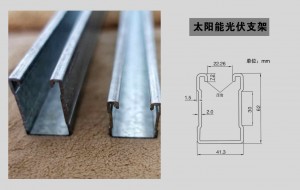

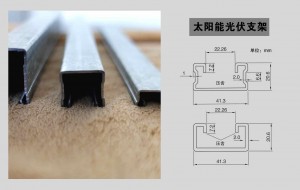

(2) ulwahlulo olunqamlezileyo: iiprofayili ze-aluminium alloy zihlala zicutshungulwa kwi-extrusion, casting, golding, stamping kunye nezinye iindlela. Imveliso ye-extrusion okwangoku yindlela yemveliso eqhelekileyo, ngokuvulwa kwe-extrusion die, inokufezekisa ukuveliswa kwayo nayiphi na iprofayili ye-cross-section engacwangciswanga, kwaye isantya semveliso sikhawuleza kakhulu.

Intsimbi isetyenziswa ngokubanzi ekucinezeleni iiroli, ekubumbeni, ekugobeni, ekunyatheleni nezinye iindlela. Ukucinezelwa kweeroli okwangoku yindlela ephambili yokuvelisa intsimbi eyenziwe ngokubandayo. I-cross-section kufuneka ilungiswe ngokusebenzisa iseti yevili loxinzelelo lweeroli, kodwa umatshini ngokubanzi unokuvelisa iimveliso ezifanayo kuphela emva kokuba iingcamango ezingaqhelekanga, ukulungiswa kobukhulu, kunye nokwakheka kwe-cross-section akunakutshintshwa, okufanaUmqadi we-C, i-Z-beam kunye nezinye izinto ezinqamlezileyo. Indlela yokuvelisa i-roller pressing izinzile ngakumbi, isantya sokuvelisa sikhawuleza.

Uthelekiso olupheleleyo lokusebenza

(1) Iiprofayili ze-aluminium alloy zikhanya ngomgangatho, zintle ngembonakalo, zinokumelana nokugqwala okugqwesileyo, zisetyenziswa ngokubanzi kwizikhululo zamandla ophahla ezifuna ukuthwala umthwalo, iindawo ezinamandla zokugqwala, ezifana nesikhululo samandla sezityalo zeekhemikhali, njl. I-aluminium alloy njengebracket iya kuba neziphumo ezingcono.

(2) Amandla aphezulu entsimbi, ukuphambuka okuncinci kunye nokuguquguquka xa kuthwalwa imithwalo, esetyenziswa ngokubanzi kwiimeko eziqhelekileyo zesikhululo samandla okanye esetyenziselwa izinto zamandla makhulu kakhulu. Ukongeza,itshaneli ye-c egalelweyoingasetyenziselwa ukwenza iibhakethi, iilori zokulayisha, iilori zokulahla inkunkuma, ii-crushers, izikhethi zepowder,Itshaneli yeGalvanizedimelana naluphi na uhlobo lokuguguleka nokukrazuka okuvela kwiintlobo ngeentlobo zamatye, isanti kunye negrabile. Isebenza kakuhle kakhulu ekudibaniseni, amandla okuchukumisa kunye nokusebenza kokugoba, ifanelekile ukusebenza kwindawo enamandla yokurhawuzelela, njengeentsimbi ezinamandla aphezulu kunye nezinto ezirhawuzelayo.

(3) Ixabiso: Ngokubanzi, uxinzelelo lomoya olusisiseko yi-0.6kN/m2, ububanzi bungaphantsi kwe-2m, kwaye ixabiso le-stent ye-aluminium alloy liphindwe ka-1.3-1.5 le-stent yesakhiwo sentsimbi. (Njengophahla lwentsimbi enemibala) i-bracket ye-aluminium alloy kunye ne-bracket yesakhiwo sentsimbi umahluko weendleko umncinci, kwaye ngokobunzima i-aluminium alloy ilula kakhulu kune-bracket yentsimbi, ngoko ke ifanelekile kakhulu kwisikhululo samandla ophahla.

Ixesha leposi: Februwari-19-2025