Advantages of square tube

High compressive strength, good bending strength, high torsional strength, good stability of section size.

Welding, connection, easy processing, good plasticity, cold bending, cold rolling performance.

Large surface area, less steel per unit surface area, saving steel.

Surrounding prongs can enhance the shear capacity of the member.

Disadvantages

Theoretical weight is larger than channel steel, high cost.

Only suitable for structures with high bending strength requirements.

Advantages of Channel steel

Higher bending and torsional strength, suitable for structures subjected to higher bending and torsional moments.

Smaller cross-section size, lighter weight, saving steel.

Good shear resistance, can be used for structures subject to large shear forces.

Simple processing technology, low cost.

Disadvantages

Lower compressive strength, only suitable for structures subject to bending or torsion.

Due to the uneven cross-section, it is easy to produce local buckling when subjected to pressure.

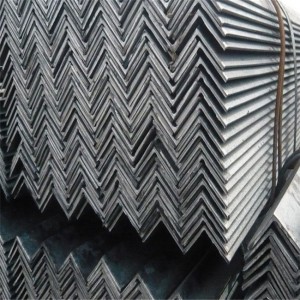

Advantages of Angle bar

Simple cross-sectional shape, easy to fabricate, low cost.

It has good bending and torsion resistance and is suitable for structures subject to large bending and torsion moments.

Can be used to make various frame structures and braces.

Disadvantages

Lower compressive strength, applicable only to structures subject to bending or torsion.

Due to the uneven cross-section, it is easy to produce local buckling when subjected to compression.

Square tubes, u channel and angle bar have their own advantages and disadvantages, and should be selected according to the actual application.

In the case of the need to withstand large compressive stress, square tube is a better choice.

In the case of large bending or torsion forces, channels and angles are a better choice.

In the case of needing to consider the cost and processing technology, channel steel and angle steel is a better choice.

Post time: Jul-25-2025