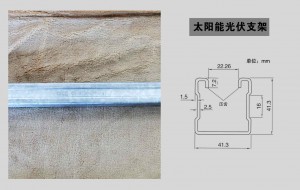

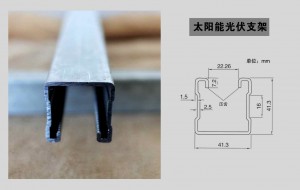

A halin yanzu, babban hanyar hana lalata ƙarfe na ƙarfe mai amfani da ƙarfin lantarki ta amfani da matattarar ƙarfe mai zafi mai ƙarfin lantarki 55-80μm, ƙarfe mai amfani da iskar shaka ta anodic 5-10μm.

Aluminum gami a cikin yanayin yanayi, a cikin yankin passivation, saman sa yana samar da wani Layer na fim mai kauri na oxide, wanda ke hana hulɗar saman aluminum matrix mai aiki da yanayin da ke kewaye, don haka yana da juriya sosai ga tsatsa, kuma ƙimar tsatsa tana raguwa da tsawaita lokaci.

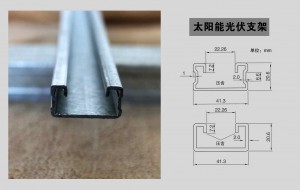

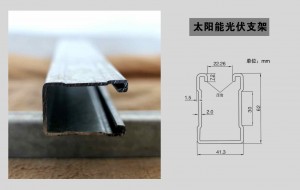

Karfe a yanayin yau da kullun (yanayin C1-C4), kauri mai kauri 80μm na iya tabbatar da amfani da shi fiye da shekaru 20, amma a yankunan masana'antu masu zafi ko kuma a yankunan teku masu yawan gishiri ko ma a yanayin zafi, yawan lalata ruwan teku yana buƙatar ya fi 100μm, kuma buƙatar kulawa akai-akai kowace shekara.

Kwatanta wasu fannoni

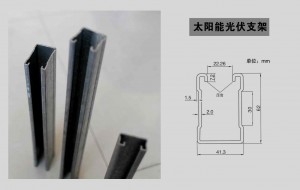

1) Bayyanar: Bayanan ƙarfe na aluminum suna da nau'ikan maganin saman abubuwa da yawa, kamar su oxidation na anodic, goge sinadarai, feshi na fluorocarbon, fenti na electrophoretic. Kamannin yana da kyau kuma yana iya daidaitawa da tasirin lalata yanayi iri-iri.

Karfe gabaɗaya ana yin amfani da shi a cikin ruwan zafi, fesawa a saman, fenti da sauransu.

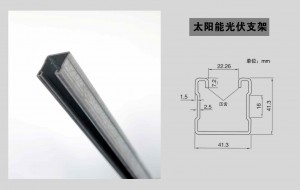

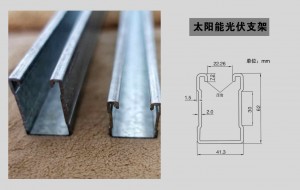

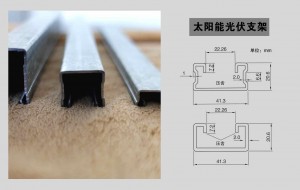

(2) bambancin sassan giciye: gabaɗaya ana sarrafa bayanan ƙarfe na aluminum ta hanyar extrusion, siminti, lanƙwasawa, tambari da sauran hanyoyi. Samar da extrusion a halin yanzu shine babban yanayin samarwa, ta hanyar buɗe murfin extrusion, zai iya cimma samar da duk wani bayanin giciye na ba bisa ƙa'ida ba, kuma saurin samarwa yana da sauri sosai.

Ana amfani da ƙarfe gabaɗaya a cikin matse na'urar, siminti, lanƙwasawa, tambari da sauran hanyoyi. Matse na'urar a halin yanzu shine babban aikin samar da ƙarfe mai sanyi. Ana buƙatar daidaita sashin giciye ta hanyar saitin ƙafafun matsi na na'urar, amma injin gabaɗaya zai iya samar da irin waɗannan samfuran ne kawai bayan an yi la'akari da ra'ayoyi daban-daban, ba za a iya canza girman da siffar giciye ba, kamarHasken C, Z-beam da sauran sassan giciye. Hanyar samar da matsi mai jujjuyawa ta fi dacewa, saurin samarwa ya fi sauri.

Kwatanta cikakken aiki

(1) Bayanan ƙarfe na aluminum suna da sauƙin inganci, suna da kyau a bayyanarsu, suna da juriya ga tsatsa, galibi ana amfani da su a tashoshin wutar lantarki na rufin da ke buƙatar yanayi mai ƙarfi na lalata, kamar tashar wutar lantarki ta masana'antu, da sauransu. Aluminum alloy a matsayin abin ɗaurewa zai sami sakamako mafi kyau.

(2) Ƙarfin ƙarfe mai yawa, ƙaramin karkacewa da nakasa yayin ɗaukar kaya, wanda galibi ana amfani da shi a yanayin yau da kullun na tashar wutar lantarki ko kuma ana amfani da shi don sassan ƙarfin yana da girma sosai. Bugu da ƙari,tashar c ta galvanizedana iya amfani da shi wajen kera bokiti, na'urorin ɗaukar kaya, manyan motocin jujjuyawa, injin niƙa, masu zaɓen foda,Tashar Galvanizedyana jure wa kowace irin lalacewa da tsagewa daga nau'ikan duwatsu, yashi da tsakuwa iri-iri. Tare da kyakkyawan aikin walda, ƙarfin tasiri da aikin lanƙwasawa, wanda ya dace da aiki a cikin yanayi mai ƙarfi na gogewa, kamar ma'adanai masu ƙarfi da kayan lalata.

(3) Kudin: Gabaɗaya, matsin iska na asali shine 0.6kN/m2, tsawonsa bai kai mita 2 ba, kuma farashin stent ɗin ƙarfe mai ƙarfe shine sau 1.3-1.5 na stent ɗin ƙarfe mai ƙarfe. (Kamar rufin ƙarfe mai launi) bambancin farashin stent ɗin ƙarfe mai ƙarfe da stent ɗin ƙarfe yana da ɗan ƙarami, kuma dangane da nauyi, sket ɗin ƙarfe mai ƙarfe yana da sauƙi fiye da sket ɗin ƙarfe, don haka ya dace sosai da tashar wutar lantarki ta rufin.

Lokacin Saƙo: Fabrairu-19-2025