Njengamanje, indlela eyinhloko yokulwa nokugqwala yensimbi ye-photovoltaic bracket isebenzisa i-hot dip galvanized 55-80μm, i-aluminium alloy isebenzisa i-anodic oxidation 5-10μm.

I-aluminium alloy endaweni yomoya, endaweni yokudlula, ubuso bayo bakha ungqimba lwefilimu ye-oxide exinene, okuvimbela ukuthi ubuso be-aluminium matrix esebenzayo buxhumane nomoya ozungezile, ngakho-ke inokumelana okuhle kakhulu nokugqwala, futhi izinga lokugqwala liyancipha ngokwandiswa kwesikhathi.

Insimbi ezimweni ezijwayelekile (indawo yesigaba se-C1-C4), ubukhulu be-galvanized obungu-80μm bungaqinisekisa ukusetshenziswa kweminyaka engaphezu kwengu-20, kodwa ezindaweni zezimboni ezinomswakama ophezulu noma ogwini olunosawoti omningi noma ngisho namanzi olwandle afudumele izinga lokugqwala liyasheshiswa, inani le-galvanization kudingeka libe ngaphezu kuka-100μm, kanye nesidingo sokulungiswa njalo ngonyaka.

Ukuqhathaniswa kwezinye izici

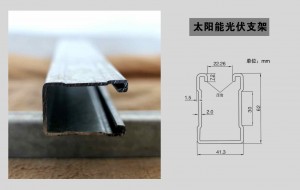

1) Ukubukeka: Amaphrofayili e-aluminium alloy anezinhlobo eziningi zokwelashwa kwendawo, njengokushisa kwe-anodic, ukupholisha kwamakhemikhali, ukufutha nge-fluorocarbon, ukupenda nge-electrophoretic. Ukubukeka kuhle futhi kungavumelanisa nemiphumela ehlukahlukene enamandla yokugqwala kwemvelo.

Insimbi ngokuvamile ifakwa i-hot dip galvanized, i-surface spray, i-pending coating njalo njalo.

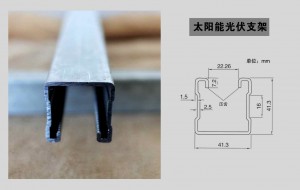

(2) ukuhlukahluka kwezingxenye: amaphrofayili e-aluminium alloy ngokuvamile acutshungulwa ngokukhipha, ukusakaza, ukugoba, ukunyathela kanye nezinye izindlela. Ukukhiqizwa kwe-extrusion okwamanje kuyindlela yokukhiqiza ejwayelekile, ngokuvulwa kwedayi ye-extrusion, kungafeza ukukhiqizwa kwanoma yimaphi amaphrofayili ezingxenyeni ezingavamile, futhi isivinini sokukhiqiza sishesha kakhulu.

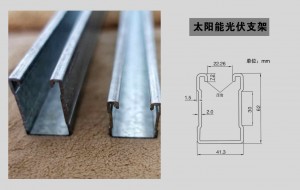

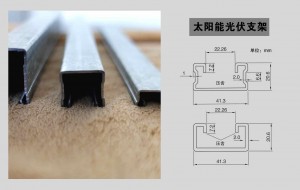

Insimbi ivame ukusetshenziswa ekucindezelweni kwama-roller, ekubunjweni, ekugobeni, ekunyatheliseni kanye nakwezinye izindlela. Ukucindezela ama-roller njengamanje kuwumkhiqizo oyinhloko wokukhiqizwa kwensimbi eyakhiwe ngendlela ebandayo. Isigaba esiphambene sidinga ukulungiswa ngokusebenzisa isethi yamasondo okucindezela ama-roller, kodwa umshini ojwayelekile ungakhiqiza imikhiqizo efanayo kuphela ngemva kokuba imibono engafani, ukulungiswa kosayizi, kanye nesimo sesigaba esiphambene singenakushintshwa, njengokuthiUmsebe we-C, i-Z-beam kanye nezinye izingxenye ezinqamulayo. Indlela yokukhiqiza yokucindezela ama-roller izinzile kakhulu, isivinini sokukhiqiza siyashesha.

Ukuqhathaniswa kokusebenza okuphelele

(1) Amaphrofayili e-aluminium alloy alula ngekhwalithi, amahle ngokubukeka, ukumelana nokugqwala okuhle kakhulu, asetshenziswa kakhulu eziteshini zamandla ophahleni ezidinga ukuthwala umthwalo, izindawo eziqinile zokugqwala, njengesiteshi samandla esitshalo samakhemikhali, njll. I-aluminium alloy njenge-bracket izoba nemiphumela engcono.

(2) Amandla aphezulu ensimbi, ukuphambuka okuncane kanye nokuguquguquka lapho kuthwala imithwalo, ngokuvamile esetshenziswa ezimweni ezivamile zesiteshi sikagesi noma esetshenziselwa izingxenye zamandla makhulu kakhulu. Ngaphezu kwalokho,isiteshi se-c esihlanganisiweingasetshenziswa ukukhiqiza amabhakede, ama-loader, amaloli okulahla imfucuza, ama-crusher, izikhethi zempuphu,Isiteshi Esihlanganisiweukumelana nanoma yiluphi uhlobo lokuguguleka okuvela ezinhlobonhlobo zamatshe, isihlabathi kanye namatshe ayigugu. Ngokusebenza kahle kakhulu kokushisela, amandla okushaya kanye nokusebenza kokugoba, kufanelekile ukusebenza endaweni enamandla okuhudula, njengezinsimbi ezinamandla aphezulu nezinto ezigqwalisayo.

(3) Izindleko: Ngokuvamile, ingcindezi yomoya eyisisekelo ingu-0.6kN/m2, ububanzi bungaphansi kuka-2m, kanti izindleko ze-stent ye-aluminium alloy ziyi-stent yesakhiwo sensimbi izikhathi ezingu-1.3-1.5. (Njengophahla lwensimbi enombala) i-bracket ye-aluminium alloy kanye ne-bracket yesakhiwo sensimbi umehluko wezindleko uncane kakhulu, futhi ngokwesisindo i-aluminium alloy ilula kakhulu kune-bracket yensimbi, ngakho-ke ifaneleka kakhulu esiteshini samandla ophahleni.

Isikhathi sokuthunyelwe: Feb-19-2025