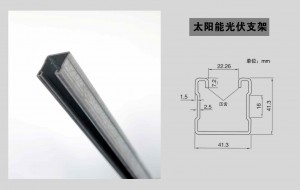

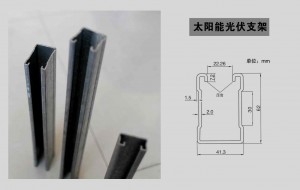

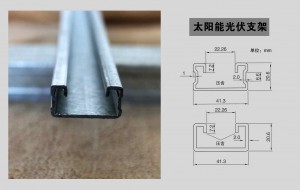

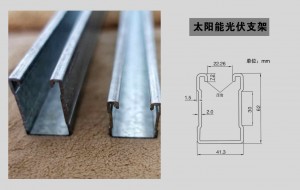

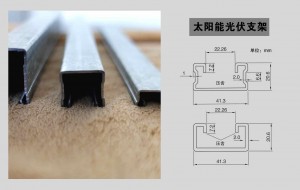

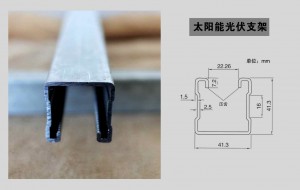

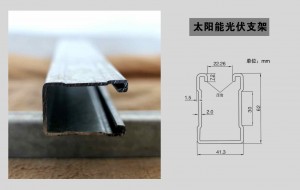

Parizvino, nzira huru yekudzivirira ngura yesimbi ye photovoltaic bracket inoshandisa kupisa kunyura kwakakamurwa 55-80μm, aruminiyamu chiwanikwa ichichishandisa anodic oxidation 5-10μm.

Aruminiyamu iri mumhepo, munzvimbo yepasi, pamusoro payo panoita jira re dense oxide film, zvichitadzisa kusangana kwe active aruminiyamu matrix nemhepo yakapoteredza, saka ine ngura yakasimba, uye ngura inoderera nekuwedzera kwenguva.

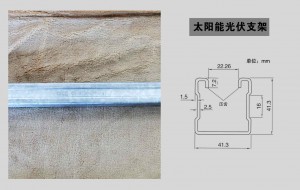

Simbi iri mumamiriro ezvinhu akajairwa (nzvimbo yeC1-C4), ukobvu hwe 80μm galvanized hunogona kuve nechokwadi chekushandiswa kwemakore anopfuura makumi maviri, asi munzvimbo dzemaindasitiri dzine hunyoro hwakawanda kana mahombekombe ane munyu wakawanda kana kunyange mvura yegungwa ine mwero wekupisa, ngura inokurumidza, huwandu hwe galvanization hunofanira kupfuura 100μm, uye kudiwa kwekugadzirisa nguva dzose gore rega rega.

Kuenzanisa zvimwe zvinhu

1) Chitarisiko: Mapurofayi ealuminium alloy ane mhando dzakasiyana dzekugadzirisa pamusoro, dzakadai seanodic oxidation, chemical polishing, fluorocarbon spraying, electrophoretic painting. Chitarisiko chacho chakanaka uye chinogona kuchinjika kune zvakasiyana-siyana zvine simba zvekuparadza kwezvakatipoteredza.

Simbi inowanzo shandiswa kupisa kudivha, kupfapfaidza pamusoro, kupeta pendi nezvimwewo.

(2) kusiyana-siyana kwezvikamu: mapurofayi ealuminium alloy anowanzo gadziriswa mu extrusion, casting, bend, stamping nedzimwe nzira. Kugadzirwa kwe extrusion pari zvino ndiyo nzira huru yekugadzira, kuburikidza nekuvhurwa kwe extrusion die, kunogona kuita kuti pave nekugadzirwa kwechero mapurofayi ezvikamu zvakasiyana-siyana, uye kumhanya kwekugadzira kuri kukurumidza.

Simbi inowanzo shandiswa mukudzvanya maroller, kukanda, kukotama, kugadzika uye dzimwe nzira. Kudzvanya maroller pari zvino ndiyo nzira huru yekugadzira simbi yakagadzirwa nechando. Chikamu chinoda kugadziriswa kuburikidza nevhiri rinodzvanywa nemaroller, asi muchina wese unogona kugadzira zvigadzirwa zvakafanana chete mushure mekunge mafungiro, saizi, uye chimiro chechikamu chinochinjika chisingagone kuchinjwa, sengeBheramu reC, Z-beam nezvimwe zvikamu. Nzira yekugadzira roller pressing yakanyanya kugadzikana, kumhanya kwekugadzira kunokurumidza.

Kuenzanisa kwakazara kwekushanda

(1) Mapurofayi ealuminium alloy ane hunhu hwakareruka, ane chitarisiko chakanaka, anodzivirira ngura zvakanyanya, anowanzo shandiswa munzvimbo dzinoda simba rekutakura zvinhu, dzine simba rengura, dzakadai senzvimbo dzinoshandisa makemikari, nezvimwewo. Alloy yealuminium sebhuraketi ichava nemigumisiro iri nani.

(2) Simba guru resimbi, kutsauka kudiki uye kushanduka-shanduka pakutakura mitoro, iyo inowanzo shandiswa mumamiriro ezvinhu akajairwa echiteshi chemagetsi kana inoshandiswa kune zvikamu zvesimba rakakura. Pamusoro pezvo,chiteshi che c chakabatidzwainogona kushandiswa kugadzira mabhaketi, ma loaders, ma dump trucks, ma crushers, ma powder selectors,Mugero WakabatidzwaInokwanisa kutsungirira chero rudzi rwekupfekwa kubva pamatombo akasiyana-siyana, jecha nejecha. Iine mashandiro akanaka ekuwelda, simba rekukanda uye mashandiro ekukombama, yakakodzera kushanda munzvimbo ine simba guru rekukwesha, senge matombo ane simba guru nezvinhu zvinoparadza.

(3) Mutengo: Kazhinji, kumanikidzwa kwemhepo kwakakosha i0.6kN/m2, hurefu hwacho huri pasi pe2m, uye mutengo we stent yealuminium alloy i1.3-1.5 times ye stent yesimbi. (Sezvakaita denga resimbi rine ruvara) bracket yealuminium alloy uye bracket yesimbi ine musiyano mudiki, uye kana tichitarisa huremu, aluminium alloy yakareruka kupfuura bracket yesimbi, saka yakakodzera nzvimbo yemagetsi padenga.

Nguva yekutumira: Kukadzi-19-2025