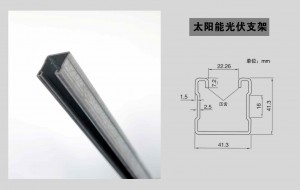

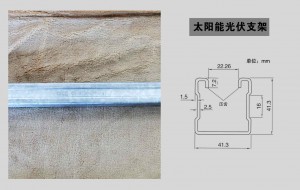

Pakadali pano, njira yaikulu yotsutsana ndi dzimbiri ya chitsulo cha photovoltaic bracket pogwiritsa ntchito kuviika kotentha kwa galvanized 55-80μm, aluminiyamu pogwiritsa ntchito anodic okosijeni 5-10μm.

Aluminiyamu yomwe ili mumlengalenga, m'dera lopanda mpweya, pamwamba pake pamapanga filimu yokhuthala ya oxide, zomwe zimalepheretsa kuti pamwamba pa aluminiyamu yogwira ntchito pasagwirizane ndi mlengalenga wozungulira, kotero imakhala ndi kukana kwabwino kwambiri kwa dzimbiri, ndipo kuchuluka kwa dzimbiri kumachepa pakapita nthawi.

Chitsulo chomwe chili m'malo wamba (malo okhala ndi gulu la C1-C4), makulidwe a 80μm galvanized amatha kutsimikizira kuti chigwiritsidwe ntchito kwa zaka zoposa 20, koma m'malo opangira mafakitale okhala ndi chinyezi chambiri kapena m'mphepete mwa nyanja momwe muli mchere wambiri kapena m'madzi otentha, dzimbiri limawonjezeka, kuchuluka kwa galvanization kuyenera kupitirira 100μm, ndipo kufunikira kokonza nthawi zonse chaka chilichonse.

Kuyerekeza zinthu zina

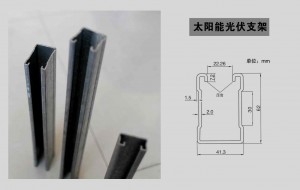

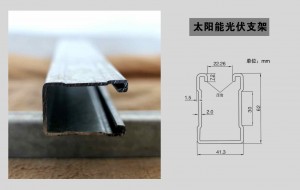

1) Mawonekedwe: Ma profiles a aluminiyamu ali ndi mitundu yambiri ya mankhwala pamwamba, monga anodic oxidation, chemical polishing, fluorocarbon spraying, electrophoretic painting. Mawonekedwe ake ndi okongola ndipo amatha kusintha kuti agwirizane ndi mphamvu zosiyanasiyana zamphamvu za chilengedwe.

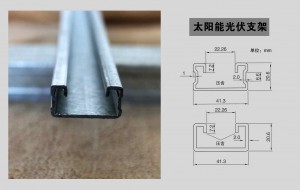

Chitsulo nthawi zambiri chimakhala chotenthetsera, chopopera pamwamba, chopaka utoto ndi zina zotero.

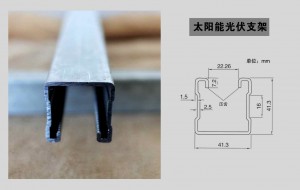

(2) kusiyanasiyana kwa magawo: ma profiles a aluminiyamu nthawi zambiri amakonzedwa mu extrusion, casting, kupinda, stamping ndi njira zina. Kupanga extrusion pakadali pano ndi njira yayikulu yopangira, kudzera mu kutsegula kwa extrusion die, kumatha kupanga ma profiles aliwonse osinthika, ndipo liwiro lopanga ndilachangu.

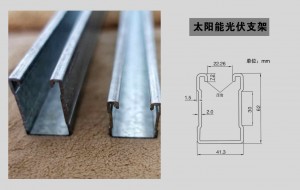

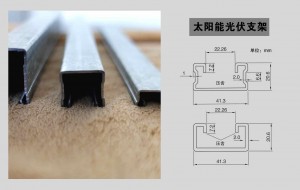

Chitsulo nthawi zambiri chimagwiritsidwa ntchito pokanikiza ma roller, kuponya, kupinda, kuponda ndi njira zina. Kukanikiza ma roller pakadali pano ndiko kupanga kwakukulu kwa chitsulo chopangidwa ndi ozizira. Gawo lopingasa liyenera kusinthidwa kudzera mu seti ya mawilo opanikizika a roller, koma makina onse amatha kupanga zinthu zofanana pokhapokha ngati malingaliro, kukula, ndi mawonekedwe a gawo lopingasa sangasinthidwe, mongaMzere wa C, Z-beam ndi zina zodutsa. Njira yopangira roller pressing ndi yokhazikika, liwiro lopanga ndi lachangu.

Kuyerekeza kwathunthu magwiridwe antchito

(1) Ma profiles a aluminiyamu ndi opepuka, okongola, okana dzimbiri, omwe nthawi zambiri amagwiritsidwa ntchito m'malo opangira magetsi padenga omwe amafunika kunyamula katundu, malo amphamvu owononga, monga malo opangira magetsi a zomera za mankhwala, ndi zina zotero. Aloyi ya aluminiyamu ngati bulaketi idzakhala ndi zotsatira zabwino.

(2) Chitsulo champhamvu kwambiri, kupindika pang'ono ndi kusinthika ponyamula katundu, zomwe nthawi zambiri zimagwiritsidwa ntchito m'mikhalidwe yanthawi zonse ya siteshoni yamagetsi kapena zomwe zimagwiritsidwa ntchito pazinthu za mphamvu ndi zazikulu. Kuphatikiza apo,njira ya c yolumikizidwa ndi galvanizingingagwiritsidwe ntchito popanga mabaketi, ma loader, malole otayira zinyalala, ma crushers, zosankha ufa,Njira Yopangidwa ndi GalvanizedImapirira kuwonongeka kulikonse kuchokera ku miyala yosiyanasiyana, mchenga ndi miyala. Imakhala ndi ntchito yabwino kwambiri yowotcherera, mphamvu yokoka komanso yopindika, yoyenera kugwiritsidwa ntchito pamalo olimba, monga miyala yamphamvu kwambiri ndi zinthu zowononga.

(3) Mtengo: Kawirikawiri, mphamvu ya mphepo yoyambira ndi 0.6kN/m2, kutalika kwake kuli pansi pa 2m, ndipo mtengo wa stent ya aluminiyamu ndi nthawi 1.3-1.5 ya stent ya kapangidwe ka chitsulo. (Monga denga lachitsulo lamtundu) kusiyana kwa mtengo wa bracket ya aluminiyamu ndi bracket ya kapangidwe ka chitsulo ndi kochepa, ndipo ponena za kulemera kwa aloyi ya aluminiyamu ndi yopepuka kwambiri kuposa bracket yachitsulo, kotero ndiyoyenera kwambiri pa siteshoni yamagetsi padenga.

Nthawi yotumizira: Feb-19-2025