Galvanized wire is manufactured from high-quality low-carbon steel wire rod. It undergoes processes including drawing, acid pickling for rust removal, high-temperature annealing, hot-dip galvanizing, and cooling. Galvanized wire is further categorized into hot-dip galvanized wire and cold-dip galvanized wire (electrogalvanized wire).

Classification of Galvanized Steel Wire

Based on the galvanizing process, galvanized wire can be categorized into the following two types:

1. Hot-Dip Galvanized Wire:

Process Characteristics: Hot-dip galvanized wire is produced by immersing steel wire into molten zinc at high temperatures, forming a thick zinc coating on its surface. This process yields a thicker zinc coating with superior corrosion resistance.

Applications: Suitable for prolonged outdoor exposure or harsh environments, such as construction, aquaculture, and power transmission.

Advantages: Thick zinc layer, excellent corrosion protection, extended service life.

2. Electrogalvanized Wire (Electroplated Galvanized Wire):

Process Characteristics: Electrogalvanized wire is produced through an electrolytic reaction that uniformly deposits zinc onto the steel wire surface. The coating is thinner but offers a smooth, aesthetically pleasing finish.

Applications: Suitable for scenarios prioritizing visual appeal over stringent corrosion resistance, such as craftsmanship and precision machining.

Advantages: Smooth surface and uniform color, though corrosion resistance is slightly lower.

Galvanized Wire Specifications

Galvanized wire comes in various specifications, primarily categorized by diameter. Common diameters include 0.3mm, 0.5mm, 1.0mm, 2.0mm, and 3.0mm. The thickness of the zinc coating can be adjusted as needed, typically ranging from 10-30μm, with specific requirements determined by the application environment and needs.

Galvanized Wire Production Process

1. Wire Drawing: Select steel wire of appropriate diameter and draw it to the target diameter.

2. Annealing: Subject the drawn wire to high-temperature annealing to enhance toughness and ductility.

3. Acid Pickling: Remove surface oxide layers and contaminants through acid treatment.

4. Galvanizing: Apply zinc coating via hot-dip or electrogalvanizing methods to form the zinc layer.

5. Cooling: Cool the galvanized wire and perform post-treatment to ensure coating integrity.

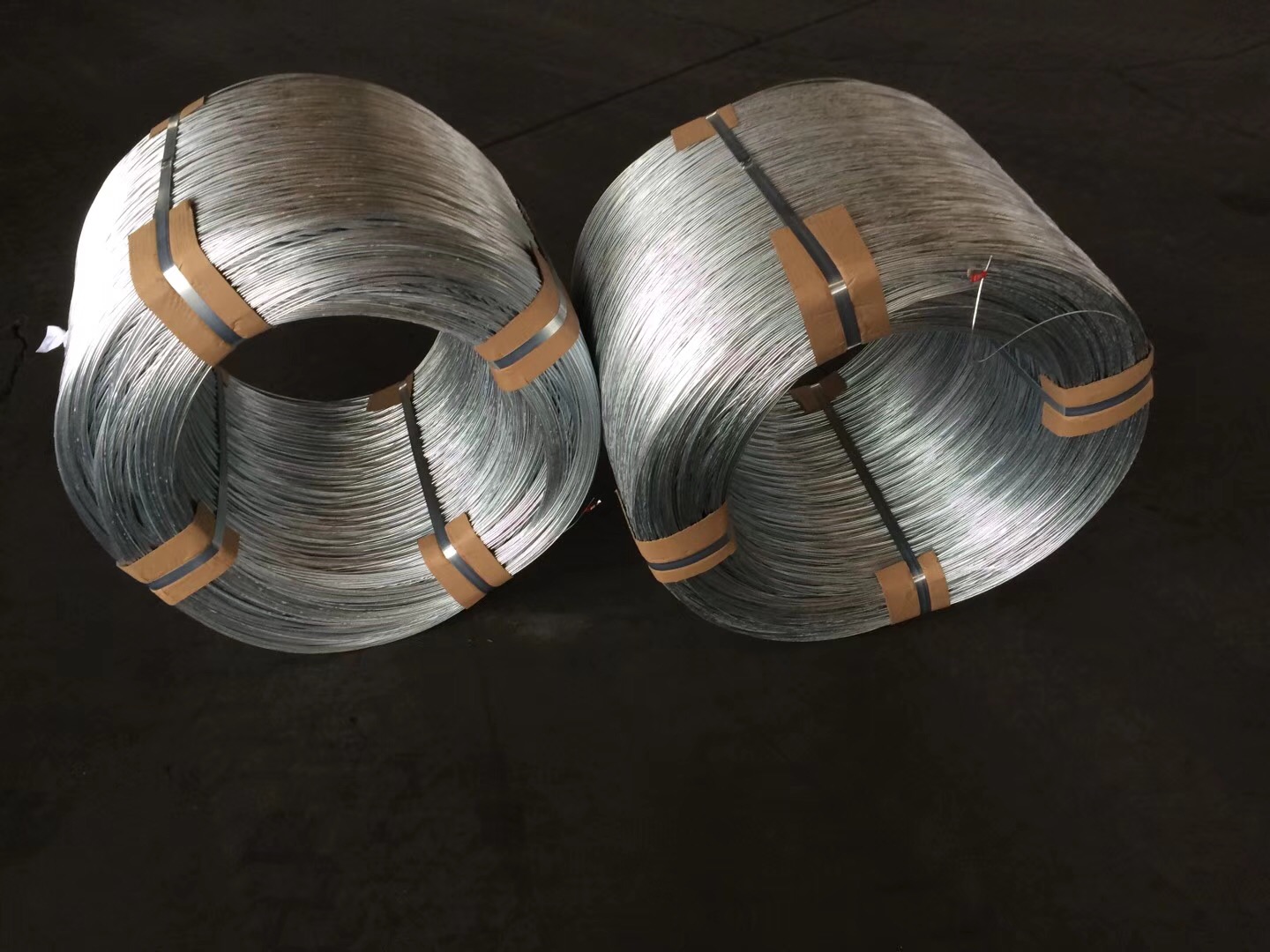

6. Packaging: After inspection, finished galvanized wire is packaged according to specifications for convenient transportation and storage.

Performance Advantages of Galvanized Steel Wires

1. Strong Corrosion Resistance: The zinc coating effectively isolates air and moisture, preventing oxidation and rusting of the steel wire.

2. Good Toughness: Galvanized wire exhibits excellent toughness and ductility, making it resistant to breakage.

3. High Strength: The base material of galvanized wire is low-carbon steel wire, providing significant tensile strength.

4. Durability: Hot-dip galvanized wire is particularly suitable for long-term outdoor exposure and offers extended service life.

5. Easy to Process: Galvanized wire can be bent, coiled, and welded, demonstrating good workability.

How do I order our products?

Ordering our steel products is very simple. You just need to follow the steps below:

1. Browse our website to find the right product for your needs. You can also contact us through website message, email, WhatsApp, etc. to tell us your requirements.

2. When we receive your quote request, we will reply you within 12 hours (if it is a weekend, we will reply you as soon as possible on Monday). If you are in a hurry to get a quote, you can call us or chat with us online and we will answer your questions and provide you with more information.

3.Confirm the details of the order, such as product model, quantity (usually starting from one container, about 28tons), price, delivery time, payment terms, etc. We will send you a proforma invoice for your confirmation.

4.Make the payment, we will start the production as soon as possible, we accept all kinds of payment methods, such as: telegraphic transfer, letter of credit, etc.

5.Receive the goods and check the quality and quantity. Packing and shipping to you according to your requirement. We will also provide after-sale service for you.

Post time: Sep-24-2025