Standard and material of ERW steel pipe

GB/T 3091-2001:Q195,Q215,Q235B, Q345B,Q345C, Q345D

ASTM A53: GrA GrB

BS1387:1985: Light A, Medium B,HeavyC

Size of ERW steel pipe

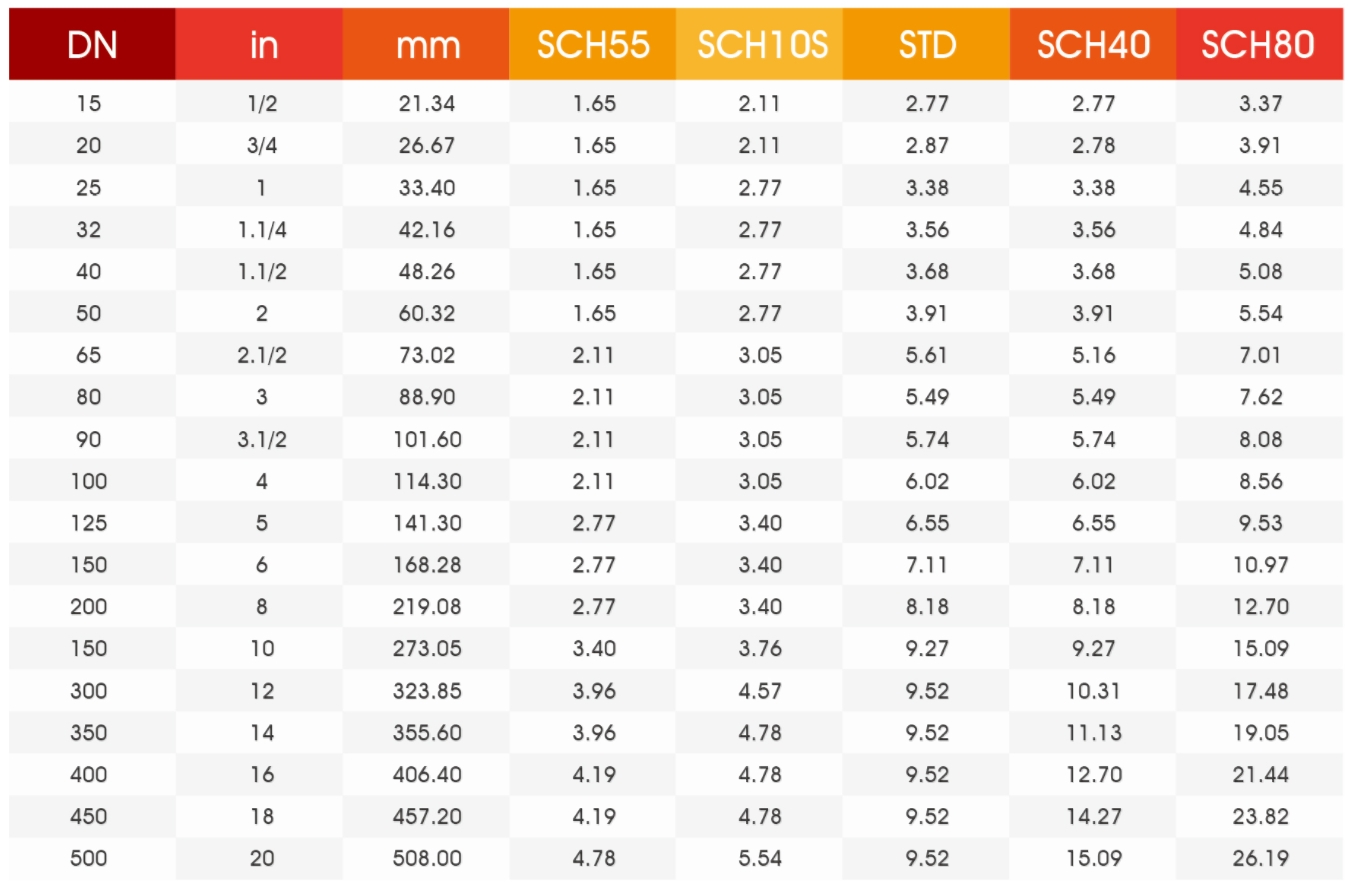

Outer Diameter: 1/2"-36” 20-914MM

Thickness:0.5mm-14mm

Advantages of Erw Round Pipe

Superior Weld Quality:ERW pipes are fabricated via electric resistance welding, a process that generates heat through electrical resistance at the seam interface, fusing the edges of the steel strip without additional filler materials. This results in a homogeneous, low-porosity weld that matches the base metal's strength, ensuring high tensile and pressure resistance.

Dimensional Precision:Manufactured with automated roll-forming and welding machines, ERW pipes offer tight tolerance control for outer diameter, wall thickness, and straightness. This precision reduces installation errors and enhances compatibility with fittings, making them ideal for applications requiring exact specifications.

Cost-Effectiveness:The continuous production process minimizes material waste and energy consumption, enabling high-volume output at a lower cost compared to seamless pipes. Additionally, their smooth inner surface reduces fluid friction, lowering long-term operational expenses in pipeline systems.

Corrosion Resistance:ERW pipes can be coated with anti-corrosive materials like zinc (galvanization), epoxy, or polyethylene, extending their lifespan in harsh environments. This versatility makes them suitable for both indoor and outdoor applications.

Customization Flexibility:Manufacturers can adjust the pipe's size, wall thickness, material grade (e.g., carbon steel, stainless steel), and end configurations (beveled, plain, threaded) to meet specific project requirements, offering tailored solutions across diverse industries.

Application Scope

Construction Industry:Steel Erw Pipe serve as structural components in buildings, bridges, and scaffolding due to their high strength-to-weight ratio. They also function as conduits for electrical wiring and plumbing systems, providing durability and ease of installation.

Oil and Gas Sector:In onshore pipelines, ERW pipes transport oil, gas, and water with reliable pressure-bearing capacity. Their corrosion-resistant coatings protect against chemical and environmental degradation, ensuring long-term operational safety.

Automotive Manufacturing:ERW pipes are used in automotive exhaust systems, chassis frames, and hydraulic tubing. Their dimensional accuracy and lightweight properties contribute to vehicle performance optimization and fuel efficiency.

Furniture and Machinery:The smooth surface and customizable shapes of ERW pipes make them popular for furniture frames, handrails, and industrial machinery components, balancing aesthetic appeal with structural stability.

Renewable Energy:In wind turbine towers and solar panel support structures, ERW pipes offer robust support while reducing material costs. Their strength and durability ensure reliable performance in renewable energy installations.

How do I order our products?

Ordering our steel products is very simple. You just need to follow the steps below:

1. Browse our website to find the right product for your needs. You can also contact us through website message, email, WhatsApp, etc. to tell us your requirements.

2. When we receive your quote request, we will reply you within 12 hours (if it is a weekend, we will reply you as soon as possible on Monday). If you are in a hurry to get a quote, you can call us or chat with us online and we will answer your questions and provide you with more information.

3.Confirm the details of the order, such as product model, quantity (usually starting from one container, about 28tons), price, delivery time, payment terms, etc. We will send you a proforma invoice for your confirmation.

4.Make the payment, we will start the production as soon as possible, we accept all kinds of payment methods, such as: telegraphic transfer, letter of credit, etc.

5.Receive the goods and check the quality and quantity. Packing and shipping to you according to your requirement. We will also provide after-sale service for you.

Post time: Apr-28-2025