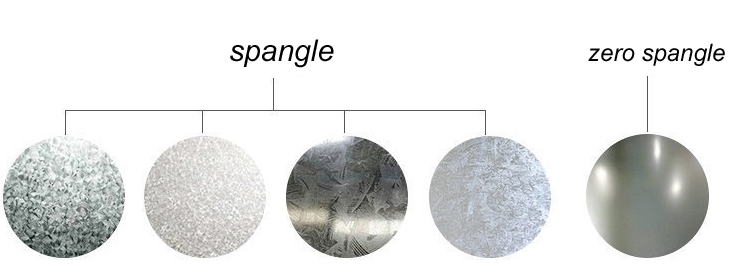

Zinc flowers represent a surface morphology characteristic of hot-dip pure zinc-coated coil. When steel strip passes through the zinc pot, its surface is coated with molten zinc. During the natural solidification of this zinc layer, nucleation and growth of zinc crystals result in the formation of zinc flowers.

The term “zinc bloom” originates from the complete zinc crystals exhibiting a snowflake-like morphology. The most perfect zinc crystal structure resembles a snowflake or hexagonal star shape. Therefore, zinc crystals formed through solidification on the strip surface during hot-dip galvanizing are most likely to adopt a snowflake or hexagonal star pattern.

Galvanized steel coil refers to steel sheets treated through hot-dip galvanizing or electrogalvanizing processes, typically supplied in coil form. The galvanizing process involves bonding molten zinc to the steel coil to enhance its corrosion resistance and extend its service life. This material finds extensive applications across construction, home appliances, automotive, machinery, and other sectors. Its excellent corrosion resistance, strength, and workability make it particularly suitable for outdoor or humid environments.

Key characteristics of galvanized steel coil include:

1. Corrosion Resistance: The zinc coating protects the underlying steel from oxidation and corrosion.

2. Workability: Can be cut, bent, welded, and processed.

3. Strength: High strength and toughness enable it to withstand certain pressures and loads.

4. Surface finish: Smooth surface suitable for painting and spraying.

Flowered galvanizing refers to the natural formation of zinc flowers on the surface during zinc condensation under standard conditions. Flowerless galvanizing, however, requires controlling lead levels within specific parameters or applying specialized post-treatment to the strip after it exits the zinc pot to achieve a flowerless finish. Early hot-dip galvanized products inevitably featured zinc flowers due to impurities in the zinc bath. Consequently, zinc flowers were traditionally associated with hot-dip galvanizing. With the advancement of the automotive industry, zinc flowers became problematic for coating requirements on hot-dip galvanized automotive sheets. Later, by reducing lead content in zinc ingots and molten zinc to levels of tens of ppm (parts per million), we achieved production of products with no or minimal zinc flowers.

| Standard System | Standard No. | Spangle Type | Description | Applications / Characteristics |

|---|---|---|---|---|

| European Standard (EN) | EN 10346 | Regular Spangle (N) | No control required over the solidification process; allows various sizes of spangles or spangle-free surfaces. | Low cost, sufficient corrosion resistance; suitable for applications with low aesthetic requirements. |

| Mini Spangle (M) | Controlled solidification process to produce very fine spangles, typically invisible to the naked eye. | Smoother surface appearance; suitable for painting or applications requiring better surface quality. | ||

| Japanese Standard (JIS) | JIS G 3302 | Normal Spangle | Classification similar to EN standard; allows naturally formed spangles. | —— |

| Mini Spangle | Controlled solidification to produce fine spangles (not easily visible to naked eye). | —— | ||

| American Standard (ASTM) | ASTM A653 | Regular Spangle | No control over solidification; allows naturally formed spangles of various sizes. | Widely used in structural components and general industrial applications. |

| Small Spangle | Controlled solidification to produce uniformly fine spangles that are still visible to the naked eye. | Offers a more uniform appearance while balancing cost and aesthetics. | ||

| Zero Spangle | Special process control results in extremely fine or no visible spangles (not discernible to the naked eye). | Smooth surface, ideal for painting, prepainted (coil-coated) sheets, and high-appearance applications. | ||

| Chinese National Standard (GB/T) | GB/T 2518 | Regular Spangle | Classification similar to ASTM standard; allows naturally formed spangles. | Widely used, cost-effective, and practical. |

| Small Spangle | Fine, evenly distributed spangles that are visible but small to the naked eye. | Balances appearance and performance. | ||

| Zero Spangle | Process-controlled to produce extremely fine spangles, invisible to the naked eye. | Commonly used in appliances, automotive, and prepainted steel substrates where surface appearance is critical. |

Industries that prefer galvanized sheets with zinc flowers:

1. General industrial manufacturing: Examples include standard mechanical components, shelving, and storage equipment where aesthetic appearance is less critical, with greater emphasis on cost and basic corrosion resistance.

2. Building Structures: In large-scale non-aesthetic structural applications like factory buildings or warehouse support frameworks, zinc-flowered galvanized sheets provide adequate protection at a cost-effective price point.

Industries that prefer zinc-free galvanized sheets:

1. Automotive Manufacturing: Exterior panels and interior trim components demand high surface quality. The smooth finish of zinc-free galvanized steel facilitates paint and coating adhesion, ensuring aesthetic appeal and quality.

2. High-End Home Appliances: Outer casings for premium refrigerators, air conditioners, etc., require excellent appearance and flatness to enhance product texture and perceived value.

3. Electronics Industry: For electronic product housings and internal structural components, zinc-free galvanized steel is typically chosen to ensure good electrical conductivity and surface treatment effectiveness.

4. Medical Device Industry: With stringent requirements for product surface quality and hygiene, zinc-free galvanized steel meets the need for cleanliness and smoothness.

Cost Considerations

Galvanized steel sheets with zinc flowers involve relatively simpler production processes and lower costs. Production of zinc-free galvanized steel sheets often requires stricter process control, resulting in slightly higher costs.

Post time: Oct-05-2025