Umbhobho wentsimbi egqunywe ngesinyithi esishushu: umbhobho wentsimbi egalelweyo eshushu kuqala ziindawo ezenziwe ngentsimbi zokugalela, ukuze kususwe i-iron oxide kumphezulu weendawo ezenziwe ngentsimbi, emva kokugalela, ngokusebenzisa isisombululo samanzi se-ammonium chloride okanye i-zinc chloride okanye iitanki zesisombululo samanzi ezixutyiweyo ze-ammonium chloride kunye ne-zinc chloride ukuze kucocwe, uze emva koko uthunyelwe kwitanki yokugalela eshushu.

Ukugaya okubandayo kukwabizwa ngokuba yi-electro-galvanizing: kukusetyenziswa kwezixhobo ze-electrolytic kuya kuba zizixhobo emva kokunciphisa amafutha, ukugalela kwi-pickling kwi-composition ye-zinc salts kwisisombululo, kwaye kuqhagamshelwe kwizixhobo ze-electrolytic ze-electrode engalunganga, kwizixhobo ezikwicala elichaseneyo lokubekwa kwepleyiti ye-zinc, eqhagamshelwe kwizixhobo ze-electrolytic kwi-electrode echanekileyo eqhagamshelwe kumbane, ukusetyenziswa kombane ukusuka kwi-electrode echanekileyo ukuya kwi-electrode engalunganga yendlela yokuhamba kwezixhobo kuya kufaka umaleko we-zinc, ukugquma okubandayo kwezixhobo kuqala kucutshungulwa kwaye emva koko kugqunywe yi-zinc.

Umahluko ophambili phakathi kwezi zimbini ngolu hlobo lulandelayo

1. Kukho umahluko omkhulu kwindlela yokusebenza

I-zinc esetyenziswa kwi-hot-dip galvanizing ifunyanwa kubushushu obuyi-450 ℃ ukuya kwi-480 ℃; kwaye ibanda.umbhobho wentsimbi egalelweyokwi-zinc, ifumaneka kubushushu begumbi ngenkqubo ye-electroplating.

2. Kukho umahluko omkhulu kubukhulu bomaleko we-galvanized

Umaleko we-zinc wepayipi yentsimbi egalelweyo eshushu ngokwawo utyebile, kukho ubukhulu obungaphezulu kwe-10um, umaleko we-zinc wepayipi yentsimbi egalelweyo ebandayo ubhityile kakhulu, ubude bungama-3-5um.

3. Ubungakanani bomphezulu obahlukeneyo

Umphezulu wombhobho wentsimbi egqunyiweyo ebandayo awugudi, kodwa xa uthelekiswa nogudi olugqunyiweyo olushushu kungcono. Nangona umphezulu ukhanya kodwa urhabaxa, kuya kuvela iintyatyambo ze-zinc. Nangona umphezulu wombhobho ogqunyiweyo obandayo uthambile, kodwa kuya kubakho umbala ongwevu, ukusebenza kakuhle kokucubungula, kunye nokumelana nokugqwala akwanelanga.

4. Umahluko wexabiso

Abavelisi, ukuze baqinisekise umgangatho, umbhobho wentsimbi ogqunywe nge-hot-dip ngokubanzi abayi kusebenzisa le ndlela yokugqunywa nge-electro-galvanized; kwaye loo mashishini amancinci anezixhobo eziphelelwe lixesha, uninzi lwawo luya kusebenzisa le ndlela yokugqunywa nge-electro-galvanized, kwaye ke ngoko ixabiso lombhobho wentsimbi ogqunywe nge-cold-galvanized liphantsi kunembhobho wentsimbi ogqunywe nge-hot-dip.

5. Umphezulu oqinisiweyo awufani

Umbhobho wentsimbi egalelweyo eshushu yipayipi yentsimbi egalelweyo ngokupheleleyo, ngelixa umbhobho wentsimbi egalelweyo ebandayo ugalelwe icala elinye kuphela lombhobho wentsimbi.

6. Umahluko omkhulu ekunamatheleni

Ukunamathela kombhobho wentsimbi egqunyiweyo ebandayo kunokubambisana kombhobho wentsimbi egqunyiweyo eshushu akukuhle, kuba umbhobho wentsimbi egqunyiweyo ebandayo kunye nomaleko we-zinc azixhomekekanga, umaleko we-zinc ubhityile kakhulu, kwaye usanamathele nje kumphezulu we-matrix yombhobho wentsimbi, kwaye kulula kakhulu ukuwa.

Umahluko kwisicelo:

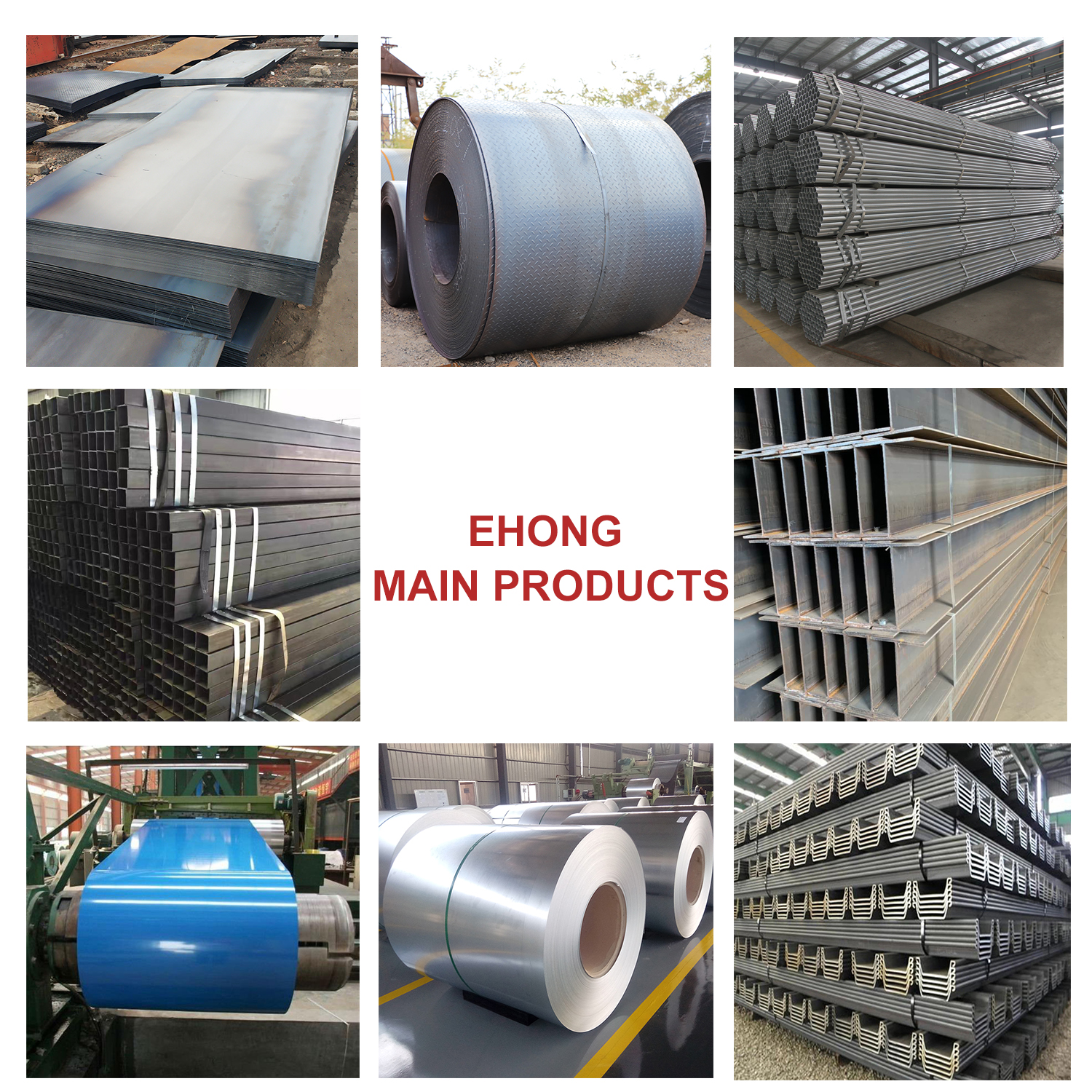

Ukuntywila okushushuumbhobho we-galvanizedisetyenziswa kakhulu kulwakhiwo, oomatshini, ukumbiwa kwamalahle, ishishini leekhemikhali, amandla ombane, izithuthi zikaloliwe, ishishini leemoto, umgaqo omkhulu, ibhulorho, isitya, izibonelelo zemidlalo, oomatshini bezolimo, oomatshini bepetroleum, oomatshini bokukhangela kunye namanye amashishini okuvelisa.

Kwixesha elidlulileyo, ipayipi ebandayo egalelweyo yayisetyenziswa rhoqo, inkqubo yokubonelela ngegesi namanzi, ngelixa kukho ezinye iinkalo zothutho lolwelo kunye nokubonelela ngokufudumeza. Ngoku ipayipi ebandayo egalelweyo ngokusisiseko isusiwe kwicandelo lothutho lolwelo, kodwa kwezinye iindawo zomlilo, amanzi kunye nesakhiwo sesakhelo esiqhelekileyo kuya kusetyenziswa ipayipi ebandayo egalelweyo, kuba ukusebenza kwe-welding yale pipe kusengcono kakhulu.

Ixesha leposi: Jan-08-2024