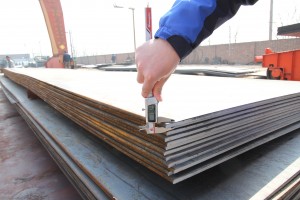

Phaj kub dovyog ib hom hlau uas tsim los ntawm kev ua kom sov thiab ua kom siab. Nws yog los ntawm kev ua kom lub billet kub mus rau qhov kub siab, thiab tom qab ntawd dov thiab ncab los ntawm lub tshuab dov hauv qab qhov kub siab kom tsim tau lub phaj hlau tiaj tus.

Loj:

Lub thickness feem ntau yog nruab nrab ntawm1.2 hlithiab200 hli, thiab qhov tuab feem ntau yog3 hli, 4 hli, 5 hli, 6 hli, 8 hli, 10 hli, 12 hli, 16 hli, 20 hlithiab lwm yam. Qhov tuab dua, qhov muaj zog thiab muaj peev xwm nqa tau ntawm cov hlau kub dov.

Qhov dav feem ntau yog nruab nrab ntawm1000 hli-2500 hli, thiab cov dav dav feem ntau yog1250 hli, 1500 hli, 1800 hli, 2000 hlithiab lwm yam. Qhov kev xaiv ntawm qhov dav yuav tsum tau txiav txim siab raws li qhov xav tau siv tshwj xeeb thiab kev siv tshuab ua.

Qhov ntev feem ntau yog nruab nrab ntawm2000 hli-12000 hli, thiab cov qhov ntev feem ntau yog2000 hli, 2500 hli, 3000 hli, 6000 hli, 8000 hli, 12000 hlithiab lwm yam. Qhov kev xaiv ntawm qhov ntev yuav tsum tau txiav txim siab raws li qhov xav tau siv tshwj xeeb thiab kev siv tshuab ua.

Kub dov kaujNws yog ua los ntawm cov slab ua cov khoom siv raw, uas yog cua sov thiab ua los ntawm roughing mill thiab finishing mill. Los ntawm laminar flow txias mus rau qhov kub teem, lub kauj yog dov rau hauv lub hlau strip coil, thiab lub hlau strip coil yog tsim tom qab txias.

Los ntawm qhov pom ntawm kev ua tau zoo ntawm cov khoom,kub dov kaujmuaj lub zog siab, zoo toughness, yooj yim ua thiab zoo weldability thiab lwm yam khoom zoo heev.

Nws tuaj yeem siv dav hauv: nkoj, tsheb, Choj, kev tsim kho, tshuab, cov hlab ntsha siab, cov khoom siv petrochemical, kev lag luam tsheb, kev lag luam tsheb ua liaj ua teb, kev lag luam nkoj, kev lag luam pej thuam, kev lag luam qauv hlau, cov khoom siv fais fab, kev lag luam ncej teeb, pej thuam teeb liab, kev lag luam yeeb nkab hlau, thiab lwm yam lag luam.

Lub sijhawm tshaj tawm: Kaum Ib Hlis-13-2023