Iintyatyambo zeZinc zimele uphawu lomphezulu we-coil ecocekileyo enezinc eshushu. Xa umcu wentsimbi udlula kwimbiza yezinc, umphezulu wayo ugqunywe yizinc enyibilikisiweyo. Ngexesha lokuqina kwendalo kolu layer lwezinc, i-nucleation kunye nokukhula kweekristale zezinc kubangela ukwakheka kweentyatyambo zezinc.

Igama elithi “zinc bloom” livela kwiikristale ze-zinc ezipheleleyo ezibonisa imo efana nekhephu. Ulwakhiwo lwekristale ye-zinc olugqibeleleyo lufana nomfanekiso wekhephu okanye inkwenkwezi enamacala asibhozo. Ke ngoko, iikristale ze-zinc ezenziwe ngokuqiniswa kumphezulu westrip ngexesha le-hot-dip galvanizing zinokwenzeka ukuba zithathe ipateni yekhephu okanye inkwenkwezi enamacala asibhozo.

I-coil yentsimbi egayiweyo ibhekisa kumaphepha entsimbi aphathwa ngeenkqubo ze-hot-dip galvanizing okanye ze-electrogalvanizing, ezihlala zibonelelwa ngendlela ye-coil. Inkqubo ye-galvanizing ibandakanya ukubopha i-zinc enyibilikisiweyo kwi-coil yentsimbi ukuphucula ukumelana kwayo nokugqwala nokwandisa ubomi bayo benkonzo. Le nto isetyenziswa kakhulu kulwakhiwo, izixhobo zasekhaya, iimoto, oomatshini, kunye namanye amacandelo. Ukumelana kwayo nokugqwala okugqwesileyo, amandla, kunye nokusebenza kakuhle kwenza ukuba ifaneleke ngakumbi kwiindawo zangaphandle okanye ezifumileyo.

Iimpawu eziphambili zeikhoyili yentsimbi egalelweyoziquka:

1. Ukumelana nokugqwala: Ingubo ye-zinc ikhusela intsimbi engaphantsi kwi-oxidation kunye nokugqwala.

2. Ukusebenza kakuhle: Inganqunyulwa, igotywe, idityaniswe, kwaye icutshungulwe.

3. Amandla: Amandla aphezulu kunye nokuqina kwenza ukuba ikwazi ukumelana noxinzelelo kunye nemithwalo ethile.

4. Ukugqitywa komphezulu: Umphezulu othambileyo ofanelekileyo ukupeyinta nokutshiza.

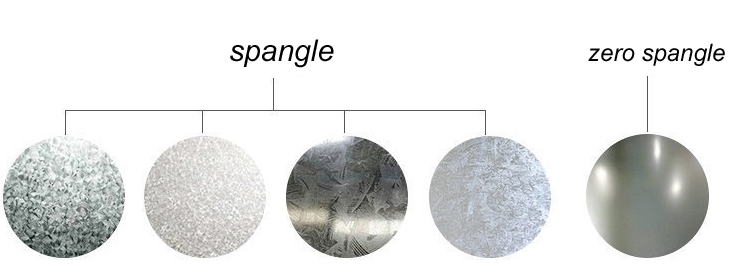

Ukugquma iintyatyambo kubhekisa ekudalweni kwendalo kweentyatyambo ze-zinc kumphezulu ngexesha lokufuma kwe-zinc phantsi kweemeko eziqhelekileyo. Ukugquma iintyatyambo ngaphandle kweentyatyambo, nangona kunjalo, kufuna ukulawula amanqanaba e-lead ngaphakathi kweeparamitha ezithile okanye ukusebenzisa unyango olukhethekileyo emva kokucoca umcu emva kokuba uphume kwimbiza ye-zinc ukuze kugqitywe ukungabi nantyatyambo. Iimveliso ze-hot-dip zakuqala ezigquma iintyatyambo ze-zinc ngokungenakuphepheka zazineentyantyambo ze-zinc ngenxa yokungcola kwi-zinc bath. Ngenxa yoko, iintyatyambo ze-zinc zazidla ngokunxulunyaniswa nokugquma iintyatyambo ezigquma iimoto. Ngokuhambela phambili kweshishini leemoto, iintyatyambo ze-zinc zaba yingxaki kwiimfuno zokugquma kwiishethi ze-zinc ezigquma iimoto. Kamva, ngokunciphisa umxholo we-lead kwii-zinc ingots kunye ne-zinc enyibilikisiweyo ukuya kumanqanaba amashumi e-ppm (iinxalenye ngesigidi), sifikelele kwimveliso yeemveliso ezingenazo okanye ezincinci ze-zinc flowers.

| Inkqubo esemgangathweni | Inombolo esemgangathweni | Uhlobo lweSpangle | Inkcazo | Izicelo/Iimpawu |

|---|---|---|---|---|

| Umgangatho waseYurophu (EN) | EN 10346 | I-Spangle eqhelekileyo(N) | Akukho lawulo lufunekayo kwinkqubo yokuqinisa; ivumela ubungakanani obahlukeneyo be-spangles okanye iindawo ezingena-spangles. | Ixabiso eliphantsi, ukumelana nokugqwala okwaneleyo; ifanelekile kwizicelo ezineemfuno eziphantsi zobuhle. |

| I-Spangle encinci (M) | Inkqubo yokuqinisa elawulwayo ivelisa ii-sangles ezintle kakhulu, ezihlala zingabonakali emehlweni. | Inkangeleko yomphezulu ethambileyo; ifanelekile ukupeyintwa okanye ukusetyenziswa okufuna umgangatho womphezulu ongcono. | ||

| Umgangatho waseJapan (iJIS) | I-JIS G 3302 | I-Spangle Eqhelekileyo | Uhlulo olufana nolwe-EN standard; luvumela ii-spangles ezenziwe ngokwendalo. | —— |

| I-Spangle encinci | Ukuqina okulawulwayo ukuvelisa ii-sparkles ezincinci (ezingabonakali lula emehlweni). | —— | ||

| Umgangatho waseMelika (ASTM) | I-ASTM A653 | I-Spangle eqhelekileyo | Akukho lawulo malunga nokuqina; ivumela ii-sangles ezenziwe ngokwendalo zobukhulu obahlukeneyo. | Isetyenziswa kakhulu kwiindawo zokwakha kunye nezicelo zemizi-mveliso ngokubanzi. |

| I-Spangle encinci | Ukuqina okulawulwayo ukuvelisa iziphandla ezicolekileyo ezifanayo ezisabonakala emehlweni. | Inika inkangeleko efanayo ngakumbi ngelixa ilinganisa iindleko kunye nobuhle. | ||

| I-Spangle Engenanto | Ulawulo olukhethekileyo lwenkqubo lubangela ukuba ii-spandels zibonakale zincinci kakhulu okanye zingabonakali (azibonakali ngeliso lenyama). | Umphezulu ogudileyo, ofanelekileyo ekupeyinteni, amaphepha apeyintwe kwangaphambili (agqunywe nge-coil), kunye nokusetyenziswa okubonakalayo okuphezulu. | ||

| Umgangatho weSizwe waseTshayina (GB/T) | GB/T 2518 | I-Spangle eqhelekileyo | Uhlulo olufana nomgangatho we-ASTM; luvumela ii-spangles ezenziwe ngokwendalo. | Isetyenziswa kakhulu, ingabizi kakhulu, kwaye iyasebenza. |

| I-Spangle encinci | Iispangles ezintle, ezisasazeke ngokulinganayo ezibonakalayo kodwa ezincinci emehlweni. | Ilinganisa inkangeleko kunye nokusebenza. | ||

| I-Spangle Engenanto | Ilawulwa yinkqubo ukuze ivelise ii-sangles ezintle kakhulu, ezingabonakaliyo ngeliso lenyama. | Isetyenziswa kakhulu kwizixhobo, kwiimoto, nakwiindawo zentsimbi ezipeyintwe kwangaphambili apho inkangeleko yomphezulu ibaluleke kakhulu. |

Amashishini akhetha amaphepha e-galvanized aneentyatyambo ze-zinc:

1. Ukwenziwa kwemizi-mveliso ngokubanzi: Imizekelo ibandakanya izinto ezisemgangathweni zoomatshini, iishelufu, kunye nezixhobo zokugcina apho inkangeleko yobuhle ingenamsebenzi kangako, kugxininiswa kakhulu kwiindleko kunye nokumelana nokugqwala okusisiseko.

2. Izakhiwo zeZakhiwo: Kwizakhiwo ezinkulu ezingezona ezintle njengezakhiwo zasefektri okanye izakhelo zenkxaso yeendawo zokugcina impahla, amaphepha e-galvanized aneentyatyambo ze-zinc anika ukhuseleko olufanelekileyo ngexabiso eliphantsi.

Amashishini akhetha amaphepha e-galvanized angenazinc:

1. Ukwenziwa kweeMoto: Iiphaneli zangaphandle kunye nezinto zokuhombisa zangaphakathi zifuna umgangatho ophezulu womphezulu. Ukugqitywa okugudileyo kwentsimbi egqunyiweyo engenazinki kwenza kube lula ukunamathela kwepeyinti kunye nokugquma, kuqinisekisa ubuhle kunye nomgangatho.

2. Izixhobo Zasekhaya Ezikumgangatho Ophezulu: Iibhokisi zangaphandle zeefriji ezikumgangatho ophezulu, ii-air conditioner, njl.njl., zifuna inkangeleko entle kunye nokuthamba ukuze kuphuculwe ubume bemveliso kunye nexabiso elibonakalayo.

3. Ishishini le-Elektroniki: Kwiindawo zokugcina iimveliso ze-elektroniki kunye nezinto zangaphakathi zesakhiwo, intsimbi ye-galvanized engenazinc idla ngokukhethwa ukuqinisekisa ukuqhuba kakuhle kombane kunye nokusebenza kakuhle konyango lomphezulu.

4. Ishishini leZixhobo zezonyango: Ngenxa yeemfuno ezingqongqo zomgangatho womphezulu wemveliso kunye nococeko, intsimbi ye-galvanized engenazinc ihlangabezana neemfuno zokucoceka kunye nokuguda.

Iingqwalasela zeendleko

Iingcamba zentsimbi ezigayiweyo ezineentyatyambo ze-zinc ziquka iinkqubo zemveliso ezilula kwaye zibiza kancinci. Ukuveliswa kweengcamba zentsimbi ezigayiweyo ezingenazo i-zinc kudla ngokufuna ulawulo olungqongqo lwenkqubo, nto leyo ebangela iindleko eziphezulu kancinci.

Ixesha leposi: Okthobha-05-2025