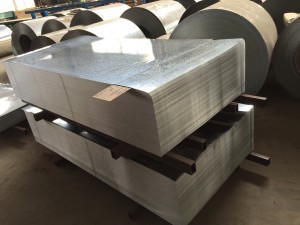

Iphepha le-galvanized lipleyiti yentsimbi enomaleko we-zinc phezu komphezulu. I-galvanizing yindlela yokuthintela umhlwa engabizi kakhulu nesebenzayo esetyenziswa rhoqo, kwaye malunga nesiqingatha semveliso ye-zinc ehlabathini isetyenziswa kule nkqubo.

Indima kaishidi le-galvanized

Ipleyiti yentsimbi egqunywe nge-galvanized yenzelwe ukuthintela ukugqwala kumphezulu wepleyiti yentsimbi ukuze yandise ubomi bayo benkonzo, igqunywe ngomaleko we-zinc yesinyithi kumphezulu wepleyiti yentsimbi, ipleyiti yentsimbi egqunywe nge-zinc ibizwa ngokuba yi-galvanized plate.

Uhlu lwephepha le-galvanized

Ngokwendlela yokuvelisa kunye nokucubungula, iindlela zingahlulwa zibe ziindidi ezilandelayo:

①Ipleyiti yentsimbi eshushu egalelweyoIsinyithi sentsimbi sintywiliselwa kwi-zinc tank enyibilikisiweyo ukuze umphezulu unamathele kumaleko wesinyithi sensimbi yesinyithi. Okwangoku, iveliswa kakhulu yinkqubo eqhubekayo yokugaya isinyithi, oko kukuthi, ukuntywiliselwa okuqhubekayo kweepleyiti zentsimbi ezigoqiweyo kwiitanki zokugquma isinyithi zesinyithi ukuze kwenziwe iipleyiti zesinyithi ze-galvanized;

② Ipleyiti yentsimbi egalelweyo exutyiweyo. Le pleyiti yentsimbi nayo yenziwa ngokuntywila okushushu, kodwa emva kokuba itanki iphumile, ifudunyezwa ngoko nangoko ukuya kuma-500 ° C ukuze kuveliswe ifilimu ye-alloy ye-zinc kunye ne-iron. Iphepha le-galvanized linamathela kakuhle kwaye liyakwazi ukudityaniswa xa ligqunywa.

③ Ipleyiti yentsimbi egalelwe ngombane. Ipleyiti yentsimbi egalelwe ngombane eyenziwe nge-electroplating iyasebenza kakuhle. Nangona kunjalo, ulusu lubhityile kwaye ukumelana nokugqwala akulunganga njengolu lwephepha le-galvanized elishushu.

④ Ipleyiti yentsimbi egqunyiweyo enamacala omabini kunye nepleyiti yentsimbi egqunyiweyo enamacala amabini. Intsimbi egqunyiweyo enamacala omabini, oko kukuthi, iimveliso ezigqunyiweyo kwicala elinye kuphela. Iyakwazi ukuguquguquka ngcono kunephepha eligqunyiweyo elinamacala amabini ekudibaniseni, ekogqumeni, ekulweni nomhlwa, ekucutshungulweni njalo njalo. Ukuze koyiswe ukusilela kwe-zinc engagqunywanga kwelinye icala, kukho iphepha eligqunyiweyo eligqunywe ngomaleko omncinci we-zinc kwelinye icala, oko kukuthi, iphepha eligqunyiweyo elinamacala amabini;

⑤ I-alloy, ipleyiti yentsimbi ehlanganisiweyo eyenziwe nge-zinc kunye nezinye iintsimbi ezifana ne-aluminium, i-lead, i-zinc, kwane-composite plating. Le pleyiti yentsimbi ayinayo nje kuphela ukusebenza kakuhle kokulwa nomhlwa, kodwa ikwasebenza kakuhle ngokugquma;

Ukongeza kwezi ntlobo zintlanu zingasentla, kukho ipleyiti yentsimbi egqunyiweyo enemibala, ipleyiti yentsimbi egqunyiweyo eprintiweyo, ipleyiti yentsimbi egqunyiweyo egqunyiweyo egqunyiweyo eplastikini, njl. Kodwa eyona isetyenziswa kakhulu iseyi-hot dip galvanized sheet.

Inkangeleko yephepha eligayiweyo

Imeko yomphezulu: Ngenxa yeendlela ezahlukeneyo zonyango kwinkqubo yokugquma, imeko yomphezulu wepleyiti egqunyiweyo nayo yahlukile, njengeentyatyambo ze-zinc eziqhelekileyo, iintyatyambo ze-zinc ezintle, iintyatyambo ze-zinc ezisicaba, iintyatyambo ze-zinc kunye nomphezulu we-phosphating.

Ixesha lokuthumela: Julayi-14-2023