Furannin zinc suna wakiltar siffar saman da aka yi amfani da shi wajen naɗa sinadarin zinc mai tsarki a cikin ruwan zafi. Lokacin da zaren ƙarfe ya ratsa ta cikin tukunyar zinc, saman sa yana da sinadarin zinc mai narkewa. A lokacin da wannan layin zinc ya taurare, nucleation da girma na lu'ulu'u na zinc suna haifar da samuwar furannin zinc.

Kalmar "furannin zinc" ta samo asali ne daga cikakkun lu'ulu'u na zinc waɗanda ke nuna yanayin dusar ƙanƙara. Tsarin lu'ulu'u mafi kyau na zinc yayi kama da dusar ƙanƙara ko siffar tauraro mai siffar hexagon. Saboda haka, lu'ulu'u na zinc da aka samar ta hanyar ƙarfafawa a saman tsiri yayin da ake nutsar da su cikin ruwan zafi suna iya ɗaukar tsarin dusar ƙanƙara ko siffar tauraro mai siffar hexagon.

Na'urar ƙarfe mai galvanized tana nufin zanen ƙarfe da aka yi wa magani ta hanyar amfani da hanyoyin galvanizing mai zafi ko electrogalvanizing, wanda galibi ana samar da shi a cikin nau'in na'urar. Tsarin galvanizing ya haɗa da haɗa zinc mai narkewa da na'urar ƙarfe don haɓaka juriyar tsatsa da kuma tsawaita tsawon rayuwarsa. Wannan kayan yana samun aikace-aikace masu yawa a cikin gine-gine, kayan aikin gida, motoci, injina, da sauran fannoni. Kyakkyawan juriyar tsatsa, ƙarfi, da kuma iya aiki ya sa ya dace musamman ga muhallin waje ko danshi.

Muhimman halaye nanada ƙarfe na galvanizedsun haɗa da:

1. Juriyar Tsatsa: Rufin zinc yana kare ƙarfen da ke ƙarƙashinsa daga iskar shaka da tsatsa.

2. Ikon Aiki: Ana iya yankewa, lanƙwasawa, walda, da kuma sarrafa shi.

3. Ƙarfi: Ƙarfi da tauri mai yawa suna ba shi damar jure wasu matsin lamba da kaya.

4. Kammala saman: Sama mai santsi da ta dace da fenti da fesawa.

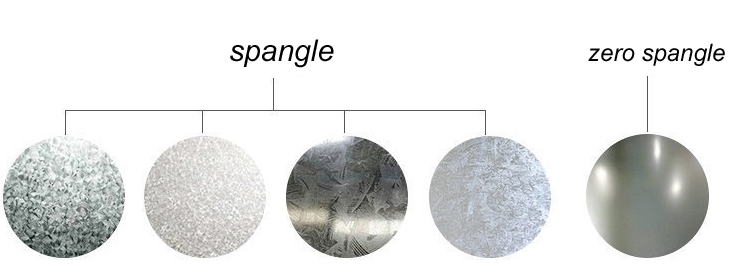

Galvanization na fure yana nufin samuwar furannin zinc a saman yanayi na halitta yayin da ake daskare zinc a ƙarƙashin yanayi na yau da kullun. Duk da haka, galvanization na rashin fure yana buƙatar sarrafa matakan gubar a cikin takamaiman sigogi ko kuma shafa musamman bayan an yi masa magani a kan tsiri bayan ya fita daga tukunyar zinc don cimma ƙarewar da ba ta da fure. Kayayyakin galvanized na farko da aka tsoma a cikin zafi ba makawa suna da furannin zinc saboda ƙazanta a cikin baho na zinc. Saboda haka, furannin zinc ana danganta su da galvanization na tsoma a cikin zafi. Tare da ci gaban masana'antar kera motoci, furannin zinc sun zama matsala ga buƙatun shafa a kan zanen mota mai galvanized na tsoma a cikin zafi. Daga baya, ta hanyar rage yawan gubar da ke cikin ingots na zinc da zinc da aka narke zuwa matakan dubun ppm (sassan kowace miliyan), mun cimma samar da samfuran da ba su da ko ƙarancin furannin zinc.

| Tsarin Daidaitacce | Lambar Daidaitacce | Nau'in Spangle | Bayani | Aikace-aikace / Halaye |

|---|---|---|---|---|

| Ma'aunin Turai (EN) | EN 10346 | Spangle na yau da kullun(N) | Babu buƙatar iko kan tsarin ƙarfafawa; yana ba da damar girma dabam-dabam na spangles ko saman da ba su da spangle. | Ƙarancin farashi, isasshen juriya ga tsatsa; ya dace da aikace-aikace masu ƙarancin buƙatun ado. |

| Ƙaramin Spangle (M) | Tsarin ƙarfafawa mai sarrafawa don samar da ƙananan spangles, yawanci ba a iya gani ga ido tsirara. | Santsi a fuskar fuska; ya dace da fenti ko aikace-aikacen da ke buƙatar ingantaccen ingancin saman. | ||

| Ma'aunin Jafananci (JIS) | JIS G 3302 | Spangle na Al'ada | Rarrabawa yayi kama da mizanin EN; yana ba da damar samar da spangles na halitta. | —— |

| Ƙaramin Spangle | Ƙarfafawa mai sarrafawa don samar da ƙananan spangles (ba a iya gani da ido tsirara cikin sauƙi). | —— | ||

| Ma'aunin Amurka (ASTM) | ASTM A653 | Spangle na yau da kullun | Babu iko akan ƙarfafawa; yana ba da damar samar da spangles na halitta masu girma dabam-dabam. | Ana amfani da shi sosai a cikin kayan gini da aikace-aikacen masana'antu gabaɗaya. |

| Ƙaramin Spangle | Ƙarfafawa mai sarrafawa don samar da ƙananan ƙusoshi iri ɗaya waɗanda har yanzu ana iya gani da ido tsirara. | Yana bayar da kamanni iri ɗaya yayin da yake daidaita farashi da kyau. | ||

| Sifili Spangle | Tsarin sarrafawa na musamman yana haifar da ƙarancin ko babu alamun da ake gani (ba a iya gane su da ido tsirara ba). | Sama mai santsi, ya dace da fenti, zanen da aka riga aka fenti (wanda aka shafa da na'urar kwali), da kuma amfani da shi sosai. | ||

| Ma'aunin Ƙasa na ƙasar Sin (GB/T) | GB/T 2518 | Spangle na yau da kullun | Rarrabawa iri ɗaya da ma'aunin ASTM; yana ba da damar samar da spangles na halitta. | Ana amfani da shi sosai, yana da araha, kuma yana da amfani. |

| Ƙaramin Spangle | Kyawawan ƙwanƙwasa masu kyau da aka rarraba daidai gwargwado waɗanda ake iya gani amma ƙanana ne ga ido tsirara. | Yana daidaita bayyanar da aiki. | ||

| Sifili Spangle | Ana sarrafa shi ta hanyar sarrafawa don samar da ƙananan spangles, waɗanda ido ba zai iya gani ba. | Ana amfani da shi sosai a cikin kayan aiki, motoci, da kuma kayan ƙarfe da aka riga aka fentin su inda yanayin saman yake da mahimmanci. |

Masana'antu waɗanda suka fi son zanen galvanized tare da furannin zinc:

1. Masana'antu gabaɗaya: Misalan sun haɗa da kayan aikin injiniya na yau da kullun, shiryayye, da kayan ajiya inda kyawun kyan gani ba shi da mahimmanci, tare da fifita farashi da juriyar tsatsa.

2. Tsarin Gine-gine: A cikin manyan aikace-aikacen gine-gine marasa kyau kamar gine-ginen masana'antu ko tsarin tallafi na rumbun ajiya, zanen galvanized mai launin zinc yana ba da isasshen kariya a farashi mai rahusa.

Masana'antu waɗanda suka fi son zanen galvanized marasa zinc:

1. Kera Motoci: Faifan waje da kayan gyaran ciki suna buƙatar ingancin saman. Santsi na ƙarfe mai galvanized mara zinc yana sauƙaƙa manne fenti da shafi, yana tabbatar da kyawun gani da inganci.

2. Kayan Gida Masu Kyau: Katunan waje don firiji masu kyau, na'urorin sanyaya daki, da sauransu, suna buƙatar kyakkyawan yanayi da laushi don haɓaka yanayin samfurin da ƙimar da ake tsammani.

3. Masana'antar Lantarki: Ga gidajen kayayyakin lantarki da sassan tsarin ciki, yawanci ana zaɓar ƙarfe mai galvanized mara zinc don tabbatar da ingantaccen watsa wutar lantarki da ingancin maganin saman.

4. Masana'antar Na'urorin Lafiya: Tare da tsauraran buƙatu don ingancin saman samfura da tsafta, ƙarfe mai galvanized mara zinc ya cika buƙatar tsabta da santsi.

La'akari da Kuɗi

Takardun ƙarfe masu galvanized da furannin zinc suna da sauƙin sarrafawa da ƙarancin farashi. Samar da takardun ƙarfe marasa zinc galibi yana buƙatar tsauraran matakan sarrafawa, wanda ke haifar da ɗan tsada.

Lokacin Saƙo: Oktoba-05-2025