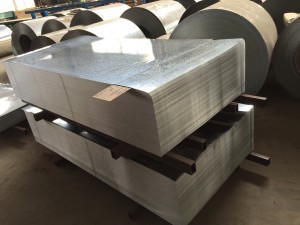

Ishidi le-galvanized liyipuleti lensimbi elinesendlalelo se-zinc phezu komhlaba. I-galvanization iyindlela yokuvimbela ukugqwala engabizi futhi ephumelelayo evame ukusetshenziswa, futhi cishe ingxenye yokukhiqizwa kwe-zinc emhlabeni isetshenziswa kule nqubo.

Indima kaishidi elihlanganisiwe

Ipuleti lensimbi elihlanganisiwe lihloselwe ukuvimbela ukugqwala ebusweni bepuleti lensimbi ukuze kwandiswe isikhathi salo sokusebenza, limbozwe ungqimba lwensimbi oluhlanganisiwe ebusweni bepuleti lensimbi, ipuleti lensimbi elihlanganiswe ne-zinc libizwa ngokuthi ipuleti elihlanganisiwe.

Ukuhlukaniswa kweshidi elihlanganisiwe

Ngokusho kohlobo lokukhiqiza nokucubungula, izindlela zokukhiqiza zingahlukaniswa ngezigaba ezilandelayo:

①Ipuleti lensimbi elishisayo elifakwe i-galvanizedInsimbi yeshidi ifakwa ethangini le-zinc elincibilikisiwe ukuze ubuso bunamathele engqimbeni yensimbi yeshidi le-zinc. Njengamanje, ikhiqizwa kakhulu ngenqubo eqhubekayo yokugaya, okungukuthi, ukucwiliswa okuqhubekayo kwamapuleti ensimbi asongiwe emathangini okugaya i-zinc ukuze kwenziwe amapuleti ensimbi ahlanganisiwe;

② Ipuleti lensimbi elihlanganisiwe. Leli puleti lensimbi lenziwa nangokucwilisa okushisayo, kodwa ngemva kokuba ithangi seliphumile, lishiswa ngokushesha lifike cishe ku-500 ° C ukuze kukhiqizwe ifilimu ye-zinc ne-iron. Ishidi elihlanganisiwe linokuqina okuhle kanye nokunamathela kahle kokumboza.

③ Ipuleti lensimbi eligayiwe ngogesi. Ipuleti lensimbi eligayiwe elenziwe nge-electroplating lisebenza kahle. Kodwa-ke, ungqimba luncane futhi ukumelana nokugqwala akukuhle njengokweshidi eligayiwe elishisayo.

④ Ipuleti lensimbi eligoqiwe elinohlangothi olulodwa kanye nelinohlangothi olubili. Insimbi egoqiwe enohlangothi olulodwa, okungukuthi, imikhiqizo egoqiwe ohlangothini olulodwa kuphela. Iyakwazi ukuzivumelanisa nezimo kangcono kuneshidi eligoqiwe elinohlangothi olubili ekushiseni, ekumbozeni, ekulweni nokugqwala, ekucubunguleni njalo njalo. Ukuze kunqotshwe ukushiyeka kwe-zinc engagqokwanga ohlangothini olulodwa, kukhona ishidi eligoqiwe elinongqimba oluncane lwe-zinc kolunye uhlangothi, okungukuthi, ishidi eligoqiwe elinohlangothi olubili;

⑤ I-alloy, ipuleti lensimbi elihlanganisiwe elihlanganisiwe. Liyipuleti lensimbi elenziwe nge-zinc nezinye izinsimbi ezifana ne-aluminium, i-lead, i-zinc, ngisho ne-composite plating. Leli puleti lensimbi aligcini nje ngokuba nokusebenza okuhle kakhulu kokulwa nokugqwala, kodwa futhi lisebenza kahle ekumbozeni;

Ngaphezu kwezinhlobo ezinhlanu ezingenhla, kunepuleti lensimbi elinombala ogqamile, ipuleti lensimbi eligqamile eliphrintiwe, ipuleti lensimbi eligqamile elimbozwe nge-polyvinyl chloride nokunye. Kodwa elisetshenziswa kakhulu kuseyishidi elishisayo elimbozwe nge-hot dip.

Ukubukeka kweshidi elihlanganisiwe

Isimo sobuso: Ngenxa yezindlela ezahlukene zokwelapha enkambisweni yokubopha, isimo sobuso bepuleti eligoqiwe sihlukile, njengezimbali ezijwayelekile ze-zinc, izimbali ezinhle ze-zinc, izimbali ezisicaba ze-zinc, izimbali ze-zinc kanye nobuso be-phosphating.

Isikhathi sokuthunyelwe: Julayi-14-2023