Ipuleti Elinezinhlayiya Ezinezinhlayiyaiyipuleti lensimbi elihlobisayo elitholakala ngokusebenzisa ukwelashwa okunephethini ebusweni bepuleti lensimbi. Lokhu kwelashwa kungenziwa ngokufaka i-embossing, ukuqopha, ukusika nge-laser kanye nezinye izindlela zokwakha umphumela wobuso ngamaphethini noma ukuthungwa okuhlukile.

Ipuleti Lensimbi Elinongwe, elaziwa nangokuthiipuleti eliqoshiwe, ipuleti lensimbi elinezimbambo ezimise okwedayimane noma ezivelele ebusweni balo.

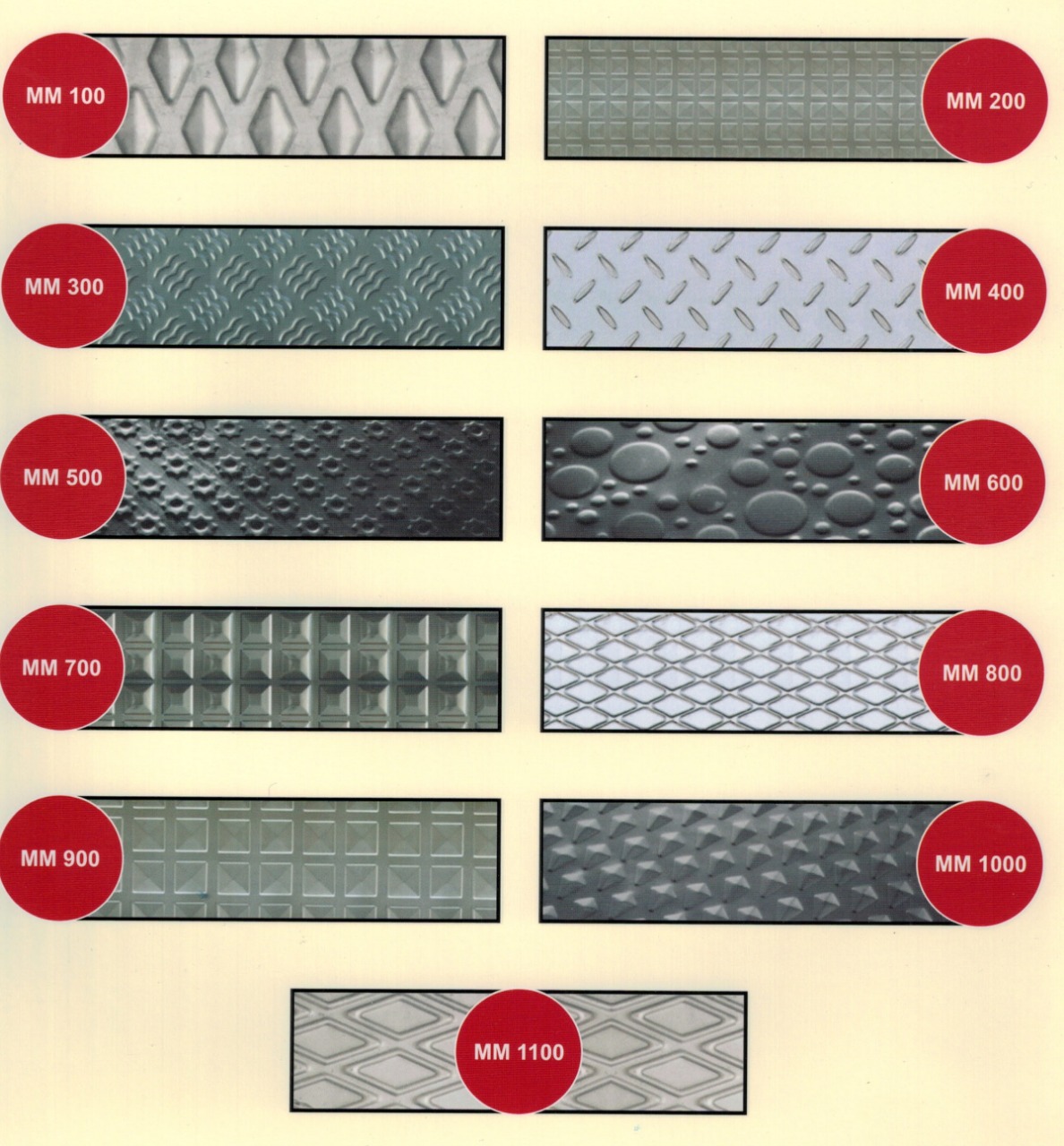

Iphethini ingaba yi-rhombus eyodwa, i-lentil noma ubhontshisi oyindilinga, noma amaphethini amabili noma ngaphezulu angahlanganiswa kahle ukuze abe inhlanganisela yepuleti elinephethini.

Inqubo yokukhiqiza insimbi enamaphethini

1. Ukukhethwa kwezinto eziyisisekelo: izinto eziyisisekelo zepuleti lensimbi elinephethini zingaba yinsimbi evamile yesakhiwo sekhabhoni egoqwe ngokubandayo noma egoqwe ngokushisayo, insimbi engagqwali, i-aluminium alloy njalo njalo.

2. Iphethini yokuklama: Abaklami baklama amaphethini ahlukahlukene, ukuthungwa noma amaphethini ngokuya ngesidingo.

3. Ukwelashwa okunephethini:

Ukuqopha: Kusetshenziswa imishini ekhethekile yokuqopha, iphethini eklanyelwe icindezelwa ebusweni be-ipuleti lensimbi.

Ukuqopha: Ngokugqwala kwamakhemikhali noma ukuqopha ngomshini, izinto ezingaphezulu ziyasuswa endaweni ethile ukuze kwakhiwe iphethini.

Ukusika nge-laser: Ukusebenzisa ubuchwepheshe be-laser ukusika ubuso bepuleti lensimbi ukuze kwakhiwe iphethini enembile. 4.

4. Ukwemboza: Ubuso bepuleti lensimbi bungaphathwa nge-anti-corrosion coating, anti-rust coating, njll. ukuze kwandiswe ukumelana kwayo nokugqwala.

Izinzuzo ze-checker plate

1. Ukuhlobisa: Ipuleti lensimbi elinamaphethini lingaba lobuciko futhi lihlobise ngamaphethini nemiklamo ehlukahlukene, linikeze ukubukeka okuhlukile kwezakhiwo, ifenisha nokunye.

2. Ukwenza kube ngokwakho: Kungenziwa kube ngokwakho ngokwesidingo, kuhambisane nezitayela ezahlukene zokuhlobisa kanye nokunambitheka komuntu siqu.

3. Ukumelana nokugqwala: Uma iphathwa ngokwelashwa kokulwa nokugqwala, ipuleti lensimbi elinephethini lingaba nokumelana nokugqwala okungcono futhi lelule isikhathi salo sokusebenza.

4. Amandla nokumelana nokuklwebheka: izinto eziyisisekelo zepuleti lensimbi elinephethini ngokuvamile ziyinsimbi yesakhiwo, enamandla aphezulu nokumelana nokuklwebheka, ezifanele ezinye izigcawu ezinezidingo zokusebenza kwezinto.

5. Izinketho zezinto eziningi: zingasetshenziswa ezinhlotsheni ezahlukene ze-substrates, kufaka phakathi insimbi evamile yesakhiwo sekhabhoni, insimbi engagqwali, ama-aluminium alloys nokunye.

6. Izinqubo eziningi zokukhiqiza: Amashidi ensimbi anephethini angakhiqizwa ngokufaka i-embossing, ukuqopha, ukusika nge-laser kanye nezinye izinqubo, ngaleyo ndlela kuveze imiphumela ehlukahlukene ebusweni.

7. Ukuqina: Ngemva kokulwa nokugqwala, ukulwa nokugqwala kanye nokunye ukwelashwa, ipuleti lensimbi elinephethini lingagcina ubuhle balo kanye nokuphila kwalo isikhathi eside ezindaweni ezahlukene.

Izimo Zohlelo Lokusebenza

1. Ukuhlobisa isakhiwo: Kusetshenziselwa ukuhlobisa udonga lwangaphakathi nolwangaphandle, uphahla, izintambo zezitebhisi, njll.

2. Ukukhiqiza ifenisha: ukwenza ideskithophu, iminyango yamakhabethe, amakhabethe kanye nenye ifenisha yokuhlobisa.

3. ingaphakathi lezimoto: lisetshenziswa ekuhlobiseni ingaphakathi lezimoto, izitimela nezinye izimoto.

4. Ukuhlobisa indawo yezentengiselwano: kusetshenziswa ezitolo, ezindaweni zokudlela, emakhefini nakwezinye izindawo zokuhlobisa udonga noma amakhawunta.

5. ukukhiqizwa kobuciko: okusetshenziselwa ukukhiqiza imisebenzi yobuciko ethile, ukubaza izithombe nokunye.

6. Uphansi olungasheleli: eminye imiklamo yamaphethini phansi inganikeza umsebenzi wokungasheleli, ofanele izindawo zomphakathi.

7. Amabhodi okukhosela: Asetshenziselwa ukwenza amabhodi okukhosela ukuze amboze noma ahlukanise izindawo.

8. ukuhlobisa umnyango namafasitela: okusetshenziselwa iminyango, amafasitela, izindonga kanye neminye imihlobiso, ukuthuthukisa ubuhle bebonke.

Isikhathi sokuthunyelwe: Ephreli-11-2024